Introduction:

Tube inserts heat exchangers are useful tools that improve tube side performance in heat exchangers. Inserts are used for applications in which tube side heat transfer is thermally limiting and an increase in pressure drop is allowed. The best insert type and design for a particular application depends on flow conditions and fluid properties. In a refinery furnace, tube inserts heat exchanger is a vital component required for preheating the throughput before it reaches the furnace, thus recovering a significant portion of energy generated in the refinery. Without heat exchangers refining cost will be substantially higher. The throughput is made to flow through a number of heat exchangers arranged as cold pre heat train and hot pre heat train before entering the furnace.

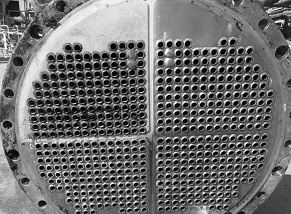

Image Of Tube Insert Heat Exchangers:

Process Of Tube Insert Heat Exchangers:

Tube inserts heat exchangers and ferrule are the same products, a metal, plastic or ceramic tube that is inserted into the end of a heat exchanger tube to provide a specific function. The purpose of a tube inserts heat exchanger is to either be sacrificial to the effects of inlet-end erosion, corrosion, impingement to induce a fluid to fall on the ID of a tube in a falling film exchanger; or to transfer extremely high heat past the tube sheet to the exchanger tubes. Each of the above applications requires a specific style of design. A metal tube insert heat exchanger is more durable in these environments. In addition, ceramics perform well when the temperatures are extremely high, however they can be subject to breaking.

Advantages Of Tube Insert Heat Exchangers:

- Sustenance of heat duty

- Reduction of fouling

- Fouling of heat exchanger tubes

- Reduced general duty

- Reduction in flow rate

- Increase in ∆P

- Reduction in productivity

- Increase in fuel consumption.

Features Of Tube Insert Heat Exchangers:

- Easy

- Quick installation

- Conforms to irregular tube surface conditions – streamlining flow over these areas

- Dimensionally stable to 170°F, well above normal operating temperatures of steam condensers

- Unaffected by normal cleaning chemicals

- Filtering action – holds foreign objects for easy removal

- Can be left in place for cleaning with most tube cleaners (consult with your sales representative)

- Available for a wide range of tube sizes and gauges.

Applications Of Tube Insert Heat Exchangers:

- Communication Cabinet

- Electric control cabinet

- Charging stations

- Food industry: Juices, beverages, sauces, dairy, deserts, fruit puree, whole fruit, catering, convenient food, pasteurization.

- Industry: Chemical, petrochemical, polymers, heating, cooling, condensation, crystallization, evaporation, energy recovery.