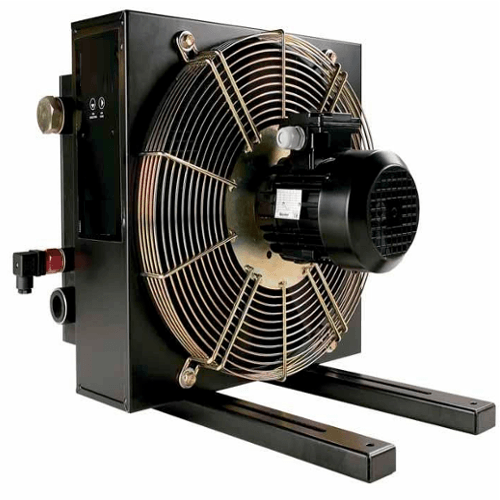

In an Air Cooled Hydraulic Oil Cooler is cooled by air streaming through, which cools down the oil. Often this type of cooler is equipped with an electric or hydraulic ventilator.

Hydraulic Motor Fan Bar Plate(plate-fin) Heat Exchanger Series Features: Aluminum bar plate fin structure, coupled with high-performance hydraulic motor and high-strength fan leaves, can be in a complex working conditions for a long time to work. Application: Hydraulic system return line, lubrication system, variable pump drain line cooling. Construction machinery (cranes, pumps, rotary drilling rig), ship metallurgical and mining machinery and other hydraulic circuit cooling.

Features Of Hydraulic Oil Cooler:

Aluminum bar plate fin structure, coupled with high-performance hydraulic motor and high-strength fan leaves, can be in a complex working conditions for a long time to work.

Application

-

In Air Cooled Hydraulic Oil Cooler Hydraulic system return line, lubrication system, variable pump drain line cooling.

-

Construction machinery (cranes, pumps, rotary drilling rig), ship metallurgical and mining machinery and other hydraulic circuit cooling.

Components

- Oil reservoir, Relief valve

- Cooling fan, radiator and mini hydraulic motor

- Filter / radiator bypass valve

- Oil level sight glass

- Filter block indicatorSuction elbow and pipe kit After mounting

Why use Oil Coolers

The two ways of cooling the oil (heated by inefficiencies in hydraulic circuits) are:

-

The more hectic and costly process is to use enough oil so that the heat created will never become too great during a single discharge.

-

A better and a more efficient process is to cool the oil so that the heat created will always be dissipated. This process allows the system to operate for unlimited periods and use less oil.

Technical Parameters

-

The displacement of the motor in the table is for reference only and can be adjusted according to the actual working conditions and requirements.

-

Motor in and out of the oil is bidirectional, the standard configuration for the suction type.

-

The maximum pressure of the outlet port: 120bar The maximum pressure of the drain: 2bar

- The noise value is a value at a distance of 1 m

Advantages

By using hydraulic oil cooler, you can get a stable cooling and filtration performance irrespective of flow and duty cycle variations of the main hydraulic circuit. This further allows the cooler to be sized to match the heat load and not the maximum return flow of the main circuit.

A bigger advantage is that this cooler is completely separated from the pressures in the return line which could potentially damage the cooler.

Also, maintenance can be performed on the filters without having to shut down the main system.

Selection Requirements

- In order to correctly size a cooler, the following parameters need to be known:

- The amount of heat that needs to be removed from the system.

- The desired oil temperature.

- The supplied water temperature and ambient air temperature

- The exact flow required

- The desired oil to water flow ratio

- The viscosity of the oil