A water-cooled condensor is a heat exchanger that removes heat from refrigerant vapor and transfers it to the water running through it. Having the refrigerant vapor condensed on the outside of a tube does this. In doing so, the vapor condenses and gives up heat to the water running inside the tube.

To size a water-cooled condenser, we must first find the total heat of rejection for the system. For an air-conditioning or high backpressure system, it is safe to size the condenser by nominal horsepower, or tons of refrigeration load. 12,000 BTU/hr is the normal figure for one ton or horsepower. To this, add 3,000 BTU/hr heat of compression for a total of 15,000 BTU/hr per ton.

Condensing water must be noncorrosive, clean, inexpensive, below a certain maximum temperature, and available in sufficient quantity. The use of corrosive or dirty water results in high maintenance costs for condensers and piping. Dirty water, as from a river, can generally be economically filtered if it is noncorrosive; corrosive water can sometimes be economically treated to neutralize its corrosive properties if it is clean. An inexpensive source of water that must be filtered and chemically treated will probably not be economical to use without some means of conservation, such as an evaporative condenser or a cooling tower.

For medium and low temperature systems, take the actual load and add 3,000 BTU/hr per horsepower.

For instance, a low temperature three-ton load with a 10 horsepower compressor would be calculated:

- 3 tons = 36,000 BTU

- 3,000 x 10 = 30,000 BTU

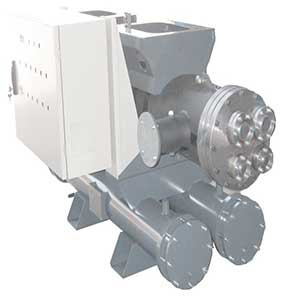

Water Cooled Condensor

- They operate at better efficiencies. Overall a water-cooled condenser unit will typically consume far less overall energy, which can lead to savings on energy costs and consumption.

- Extended lifespan. Because of the efficiency of the medium, and the lack of weather-exposed parts, a water-cooled system will typically last years longer, assuming maintenance is not neglected.

- Can operate better at higher temperatures. Industries such as manufacture may find that water-chilled systems operate more effectively in high-temp areas.