Introduction Of Heat Exchangers :

Heat exchanger is a device designed to efficiently transfer or “exchange” heat from one matter to another. When a fluid is used to transfer heat, the fluid could be a liquid, such as water or oil, or could be moving air. The most well known type of heat exchanger is a car radiator. In a radiator, a solution of water and ethylene glycol, also known as antifreeze, transfers heat from the engine to the radiator and then from the radiator to the ambient air flowing through it. This process helps to keep a car’s engine from overheating. Similarly, Lytton’s heat exchangers are designed to remove excess heat from aircraft engines, optics, x-ray tubes, lasers, power supplies, military equipment, and many other types of equipment that require cooling beyond what air-cooled heat sinks can provide.

Process Of Heat Exchangers:

Process of heat exchangers are Temperature homogenization is achieved for high viscous and temperature sensitive products. The quality of these products is at par with the international standards, which increases their durability and stability. They provide optimum levels of heat exchange be it any type of liquids, gases or vapours. The components to be mixed are pumped at the inlet of the mixing unit containing static mixing elements. Due to the construction of the mixing elements, the fluids are directed radically outwards and inwards while the forward flow continues. This movement is multiplied by introducing more number of mixing elements. The angle of this movement is also changed by subsequent elements. As a result, the mixing effect is achieved with the fluid emerging out at the other end.

Equipment And Machinery:

Computerised fin Lines, Hairpin Benders, mechanical Expander, Automatic Brazing Machine, CNC Turret punch, press Brake, shear, CNC Pipe Bending Machines, Pipe Flaring, Expanding, beading Equipment, Return Bend manufacturing, Tig / Mig welding, Tin Plating and Painting apart from other equipment required for manufacturing world class Heat Exchangers.

Features Of Heat Exchangers:

- With RS485 communication interface, it can be real-time monitored.

- Energy saving and environmental protection.

- Low temperature compensation, no cooling to condensation.

- Requires low maintenance

- Multipurpose usage

- Efficient heat elimination

- Durable and stable

- Made from reliable raw material

- Sturdy construction

- Less maintenance

- Corrosion & abrasion resistance.

Applications Of Heat Exchangers:

Communication Cabinet, Electric control cabinet, Charging stations, Food industry: Juices, beverages, sauces, dairy, deserts, fruit puree, whole fruit, catering, convenient food, pasteurization, Industry: Chemical, petrochemical, polymers, heating, cooling, condensation, crystallization, evaporation, energy recovery, Environmental: Waste water, environmental waste concentration, evaporation, sludge, pasteurization, Bio-energy: Bio ethanol, biodiesel, biogas, cogeneration.

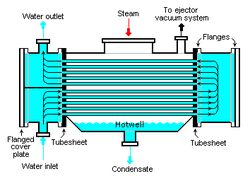

Images Of Heat Exchangers: