Introduction:

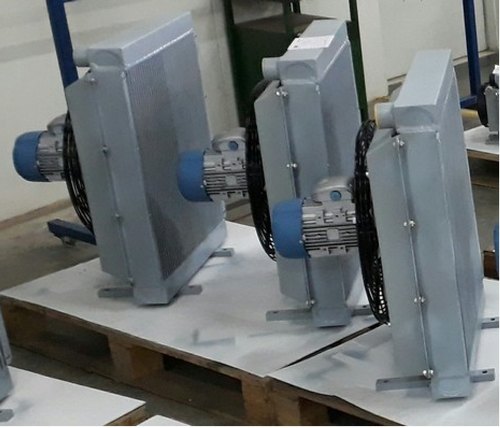

Air blast heat exchangers are also called forced draft oil cooler. This is because the cooling in done by external fan. Here the oil is passed thru radiator & behind the radiator there will be fan which blows over the radiator thus cooling the oil. Radiators are made up of cooper tube with aluminum fins. Aluminum fins are bounded to the copper by expanding the cooper tube by high pressure water. We have designed & developed certain models considering the hydraulic system which are normally used in the industries. We also supply custom built design as per the customer’s requirements. Its are normally supplied with AC power supply. We also supply with DC power supply and with shaft driven pulley.

Process Of Air Blast Heat Exchangers:

Air blast heat exchangers are manufacturing process also imparts the ability to incorporate many enhancements such as louvers, air turbulators and vortex generators. Our expertise in the use of vortex clean air technology reduces pressure loss and fin fouling, resulting in lower maintenance costs and reduced energy consumption. Compare this to some of the alternative construction methods used by many of our competitors, one of the most common being bullet-expansion. This method commonly results in varying levels of contact between the tubes and the fins as variations and inconsistencies in tube diameter, thickness and joviality take their toll. This construction method also greatly restricts material choice, tube thickness and shape. Its are manufactured using custom built, state-of-the-art CNC machines incorporating advanced electronics and linear motor technology. This results in excellent fin-to-tube contact for optimum thermal conductivity and increased consistency of fin placement for minimal pressure drop in stacked rows.

Images :

Benefits Of Air Blast Heat Exchangers:

- Its are as no hydraulic system can convert mechanical to hydraulic energy with 100% efficiency, heat is always going to be produced in the system as a by product.

- This means there will be a rise in the oil temperature that must be controlled in order to optimise the performance of your system.

- As the temperature of the oil rises, its viscosity drops and the oil will lose its lubricating properties. This can affect seals and ‘O’ rings and can ultimately damage the whole system. At best the oil will have to be changed frequently at considerable cost.

Applications Of Air Blast Heat Exchangers:

- Charge air coolers

- Alternator air coolers

- Boiler feed pump heaters/coolers

- Diesel generator air coolers

- Gas circulator motor air coolers

- Generator air coolers

- Heating coils

- Main engine charge air coolers

- Motor air coolers

- Scavenge air coolers

- Waste heat recovery units