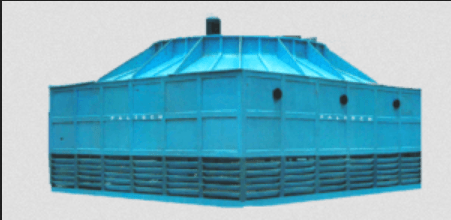

Square Shape Counter Flow Cooling Towers:

Square shape Counter flow cooling towers are fitted with an induced draught fan on the top and are directly mounted on the motor. The fan induces the ambient air into the tower to draft it upward. As a result, the speed of exhaust air is much higher than the air that enters. These results in low pressure drop and also lower circulation. Square shape Counter flow cooling tower design allows maximum thermal performance capability per unit of plan area. Minimizes pump head requirements. Available with your choice of heat exchange media to satisfy just about any water quality.

Image:

Process:

The square shape counter flow cooling tower performs on counter flow mechanism, in which the air drafts vertically upwards through the fillings/packing, while the water splashes downwards. Square shape Counter flow design is more suitable for the application, where cold water temperature is critical.

One of the main advantages of counter flow design is that the coldest water contacts the driest air resulting in the maximum tower performance. Being an enclosed device, a counter flow cooling tower eliminates the possibility of sunlight exposure of water. This minimizes the possibility of growth of algae. A nozzle distribution is sensitive to changes in water flow thus it affects the overall efficiency.

The air movement is vertically through the fill in counter flow to the downwards fall of the water. Square shape Counter flow towers have in general a smaller footprint than cross flow towers but require a higher pump head due to the typical distribution system with nozzles.

Materials:

1. Direct Driven Fan:

1. Aluminium Alloys/engineered polymer/FRP fans for higher capacity to resist and lifelong

2. Low weight, low energy consumption

3. Axial flow, aerodynamic, maximum air throws higher cfm

4. Adjustable blades, it can increase or decrease air flow

5. G.m.bush and sus bolt nuts hardware available at extra cost

2. Electric motor:

1. IP 55 weather proofing gives excellent resistance to bad weather impact

2. ‘ f ‘ class insulating can resist higher temperature or heat

3. Low rpm eliminate gear drive or, ‘v’ belt arrangement and reduce maintenance

4. Flange mounted top side located less maintenance

5. Long shaft arrangement and fitting no requirement of couples or joint part as direct driven

3. Fills Packing:

1. Honey comb pattern ensure to distribute water equally

2. Cross design ribs properly allow maximum air contact with water

3. PVC raw material withstand heat

4. Exclusive Spray System with Jet Atomising Nozzles:

1. Unique design best splashing water most of fill area

2. Zero breakdown and maintenance [no rotating part]

3. Best suitable for dusty and polluted area

4. Jet atomising nozzles easy to replace, affordable cost, easy availability

5. G.i.pipes/upvc /cpvc and distributer and branches for corrosion and rust free

5. FRP Casing and Basin:

1. Light weight structure with sturdy design compare to m.s.steel reduces. Work cost.

2. More resistance capacity in water, weather & enhance life of cooling tower

3. Gel coated surface for fabulous appearance and resist in sunlight

4. High grade FRP raw materials it is compatible to m.s.steel strength, and gives durability

6. Other Frame Work:

1. Standard m.s.steel gives better durability and reducing replacing or repairing cost

2. Standard duly hot dip galvanising ensures resistance to rust, extending life

3. Perfect engineering and design for ease of maintenance [replacing and repairing]

7. Hardware:

1. Standard make & sizes sustains and better durability in worse weather condition

2. Galvanising gives long life.

Features:

- Durability

- Low maintenance

- Easy operations

- Scientifically and elegantly designed Fibre Glass Reinforced Plastic ( FRP) Cooling towers

- Precision fabrication ensures effective cooling power

- Economically priced, durable and dependable.

- Square and rectangle shape design

- FRP body & basin for well-built design, good appearance

- Polymer non-clog type nozzles to reduce maintenance

- Honeycomb fills packing for optimum air and water contact.