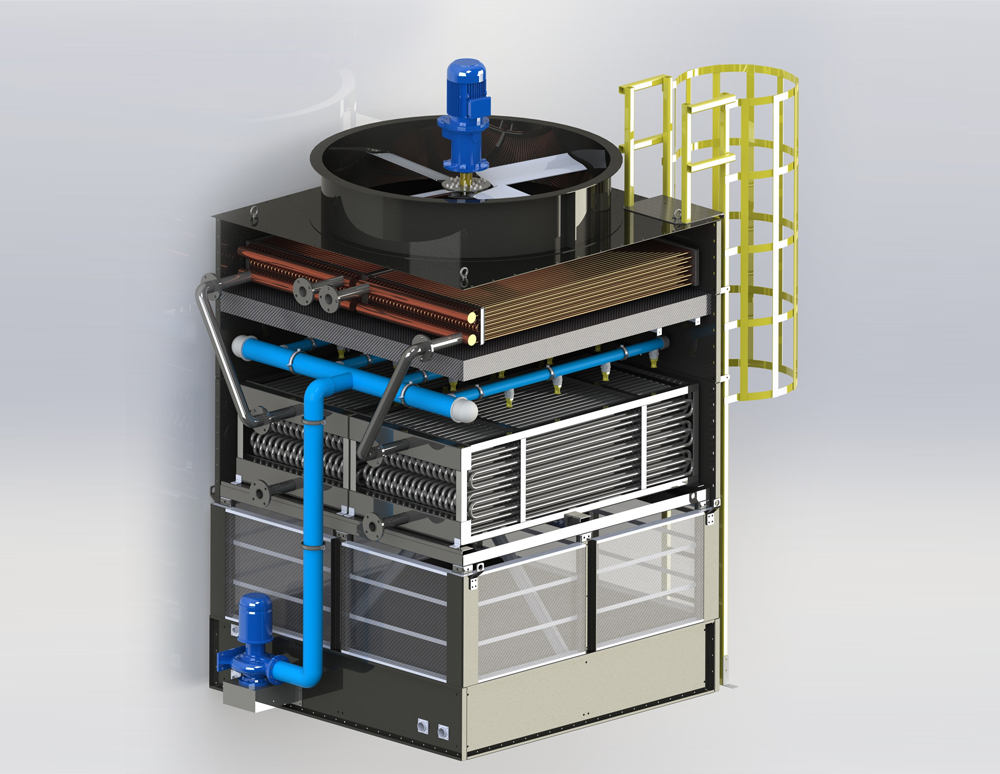

Closed Circuit Hybrid Cooling Towers

Introduction:

Closed Circuit Hybrid Cooling Towers deliver fully rated thermal performance over a wide range of flow and temperature requirements. Distinct advantages of the Hybrid include plume abatement, significant water savings over traditional water-cooled equipment, and its suitability for high temperature cooling (>80 °C).

Benefits:

- The HXV offers a combination of sensible, adiabatic, and evaporative heat transfer to significantly reduce any plume that may occur with conventional evaporative cooling equipment.

- During the coldest times of the year, when the potential for visible discharge is greatest, the HXV operates 100% dry, completely eliminating plume.

- At peak conditions in the “dry/wet” operating mode, a significant amount of heat is removed by sensible heat transfer, providing reduced water consumption versus conventional evaporative cooling.

- High efficiency, low horsepower axial fans

- Closed loop cooling, which minimizes process fouling

- Support — All models mount directly on parallel I-beams and ship complete with motors and drives factory-installed and aligned.

- Modular Design — Units ship in three pieces to minimize the size and weight of the heaviest lift, allowing for the use of smaller, less costly cranes.

- Access — Hinged access doors on each end wall and a standard internal walkway provide easy access to the unit interior.

- Separate Air Inlet Louvers — Reduce the potential for scale build-up and damaging ice formations at the air/water interface by providing a line of sight from the outside of the unit into the fill.

Closed Circuit Hybrid Cooling Towers Process:

First, the process fluid is circulated through the dry coil. A portion is of the heat is rejected to the air passing over the dry coil. The process fluid then enters the wet coil where the remaining heat of the process fluid is transferred through the tube wall to the water cascading downward over the tubes. Simultaneously, air is drawing in through the air inlet louvers at the base of the cooler and travels upward over the coil opposite the spray water flow. A small portion of the water is evaporated which rejects heat. The warm moist air is drawn to the top of the closed circuit cooler by the fan and is discharged to the atmosphere. The remaining water falls to the sump at the bottom of the cooler where it is recirculated by the pump through the water distribution system and back down over the coils.

TECHNICAL INFORMATIONS

- The company is the only one manufacturer in Turkey that produces dry finned coils and evaporative coils in its factory.

- At peak conditions in the “dry/wet” operating mode, a significant amount of heat is removed by sensible heat transfer, providing reduced water consumption versus conventional evaporative cooling.

- When the heat load and/or ambient temperatures drop, water consumption is further reduced in the “adiabatic” operating mode.

- Water consumption is totally eliminated in the “dry” operating mode.

- The finned dry coil tempers the incoming fluid, allowing higher inlet fluid temperatures than traditional closed circuit cooling towers.

- In DRY mode, the spray water is turned off, saving pump energy, and the fluid to be cooled is circulated through both the finned and prime surface coils.

- During the coldest times of the year, when the potential for visible discharge is greatest, the Hybrid Cooling Tower operates 100% dry, completely eliminating plume.

Images:

Closed Circuit Hybrid Cooling Towers