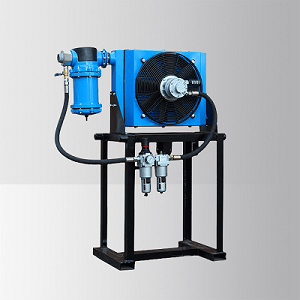

After Cooler heat exchanger

After Cooler heat exchnager will reduce the temperature of air from a compressor down to within 8 Deg.C of the cooling water temperature. They should be mounted in a vertical position with a moisture separator inserted in the air-line immediately after the air outlet from the cooler. To avoid undue strain on the after cooler heat exchanger long lengths of unsupported pipes should be avoided.

For product application and rating information please contact our technical sales department for assistance.

two cooling concepts for after cooler heat exchangers:

- For use when the ambient air is cool enough and without a water source: Air cooling (cross-flow heat exchanger, ACA series).

- For achieving very low temperatures: Water cooling (shell and tube heat exchanger, WRN series).

The heated cooling air can be used for hall-heating purposes, whilst the heated cooling water can be used in water treatment systems, for example, for drying sludge.

Advantages of After Cooler Heat Exchanger

- Full energy transfer:

Our aftercoolers / heat exchangers are specifically designed for use with Kaeser blowers. This keeps flow and pressure losses to an absolute minimum, therefore allowing all of the input energy to be available for further use. - The right aftercooler / heat exchanger for every need:

We will select the perfect aftercooler / heat exchanger for your specific pressure and temperature needs from our comprehensive product range. This means greater efficiency and a longer service life. - Protection of temperature-sensitive bulk materials:Aftercoolers / heat exchangers reliably lower the air temperature. The quality of temperature-sensitive bulk materials such as baking mixes, animal feed or plastic granules is not compromised.

About:

They should be mounted in a vertical position with a moisture separator inserted in the air-line immediately after the air outlet from the cooler. To avoid undue strain on the after cooler heat exchanger long lengths of unsupported pipes should be avoided.

The variety of degradation modes challenges the integrity of tubing and, therefore, the stations’ reliability. Inspection and monitoring aimed at timely detection and characterization of the degradation is a key element for ensuring tube integrity. Generator heat exchangers incorporates the bobbin probe, primarily for volumetric indications such as pitting and fretting, and the X-probe which is a T/R (transmit/receive) array probe used for detection of axial or circumferential indications, along with volumetric indications.

Image: