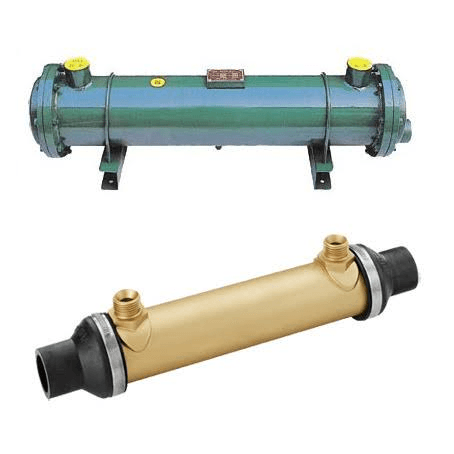

Oil Cooled Heat Exchangers:

Overview:

Oil cooled heat exchangers are water shortage and increasing costs, together with more recent concerns about water pollution and cooling tower plumes, have greatly reduced industry’s use of water cooled heat exchangers. Consequently, when further heat integration within the plant is not possible, oil cooled heat exchangers are now usual to reject heat directly to the atmosphere, and a large proportion of the process cooling in refineries and chemical plants takes place in this Heat Exchangers . Oil cooled equipment can be a more simple solution against water cooled because in water cooled systems typically there is also a need for more pumps, piping, central chillers or cooling towers increasing the operating cost and maintenance of the system.

Process:

The oil cooled heat exchangers system consists of an aluminium coated steel flat duct. Aluminium finings between the flat ducts are hard-soldered to the aluminium coating of the flat duct. There is also increasing use of oil Cooled Condensers for power stations. The basic principles are the same but these are specialized items and are normally configured as an A-frame or “roof type”. Oil cooled heat exchangers are may be very large—the condensers for a 4000 MW power station in South Africa have over 2300 tube bundles, 288 fans each 9.1 m in diameter and a total plot area 500 m × 70 m. The solder fills the gap between the fin root and the core tube completely to achieve excellent heat transfer properties.

Image:

Materials:

- Carbon Steel with or without NACE requirement and / or HIC testing.

- Chromium Molybdenum Alloy Steel.

- Stainless Steel Alloys.

- Duplex Stainless Steel Alloys.

- Nicolay.

- Welding procedures are already established for Inconel and Titanium materials and hence capability exists for these metallurgy too.

Features:

- Used across several industries

- Hi tech technology used

- Top class quality

- Excellent performance

- High durability

- Low cost

- Low maintenance

- Designed and constructed as per is, din or team std

- Deprived from intermixing fluids

- Construction is done to make the shell & tube sheet materials wieldable

- U-tube bundle : this type of heat exchanger finds applications in fuel systems like fuel oil suction heater. If the tube side velocity is less and the allowable pressure drop is less, this type is preferred. This type is suitable for condensing vapours and clean tube side fluids.

Advantages:

- Prevention of thermal and chemical pollution of cooling fluids (closed circuits)

- Flexibility for any plant location and plot plan arrangement (installation over other units)

- Reduction of maintenance costs

- Easy installation by bolted assembly

- Lower environmental impact than shell and tube heat exchangers thanks to the elimination of an auxiliary water supply

Applications:

- Trucks and Buses

- Utility and Military Vehicles

- Railway Engines and Rolling Stock

- Gas and Diesel Engines

- Construction Equipment

- Agricultural and Mining Equipment

- Generator Sets

- Performance Cars