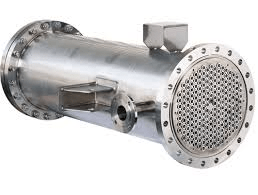

Heat Transfer Equipment Heat Exchangers:

Heat transfer equipment heat exchangers are found to be useful in a wide range of industries. They can be broadly defined as equipment’s used for transfer of heat from a hot medium to cold medium. Heat exchanger design and structure of these equipment varies a lot depending on the application where they are used and the heat transfer media involved heat transfer is comprised of two components: flow of heat and temperature. The flow of heat represents the movement of energy from one place to another and temperature is the measure of thermal energy available. Thermal energy is also known as kinetic energy, or energy in motion. We will focus on fluid heat exchangers, since that is what we at Cooling Technology, Inc. specialize in.

Image:

Process:

Principles of heat transfer equipment heat exchangers are Fluid heat transfer systems circulate thermal fluid through process equipment to maintain an even consistent temperature. Tanks, pipes, pumps, and heating and/or cooling systems are used to circulate water, steam, hydrocarbon oils, and glycols. Heat sources include electricity, natural gas, propane, fuel oil, and solar power. Cooling sources primarily use air and water. Glycols are added to water to prevent freezing in process temperatures below 32°F. The most common type of heat transfer equipment is a shell and tube exchanger which consists of a series of small tubes with the fluid flowing through these tubes. The other liquid runs over these inner tubes while encased in a larger shell. Brazed Plate and Plate & Frame heat exchangers are another type which direct the flow through a waffled surface area. The fluids are separated by plates. This heat exchanger can be more efficient than a shell and tube heat transfer system.

Features:

- Designed to deliver excellent heat transfer in an efficient manner

- Ability to withstand high pressures

- Reliable functioning

- Specifically designed

- Smooth functioning

- Can bear high temperature

- Robust construction

- Easy operation

- High efficiency

- Smooth functionality

- Specifically designed

- Smooth functioning

- Can bear high temperature

Applications:

- Air-cooled heat exchangers, Boilers, Burners, Chillers, Condensers, Dryers, Evaporators, Flares, Heaters, Heating and cooling tanks, Ovens, Plate type exchangers, Re boilers, Shell and tube heat exchanger and super heaters.

- Based on calculations of thermal power & energy consumed through measurement of flow, temperature difference of inlet & outlet of the medium.

- 4-20 mA output proportional to power output.

- 16×2 LCD, 9 digits for total energy & 5 digits for instantaneous power.

- The engineering unit can be selected as either KW & KWHr or BTU/hr. & BTU.

- Communication port RS 232/485 is available with MODBUS RTU.

- Backup of totalize on power failure in non volatile memory.

- Logging history can be viewed on the screen.

- Ingress Protection: IP65 Equivalent