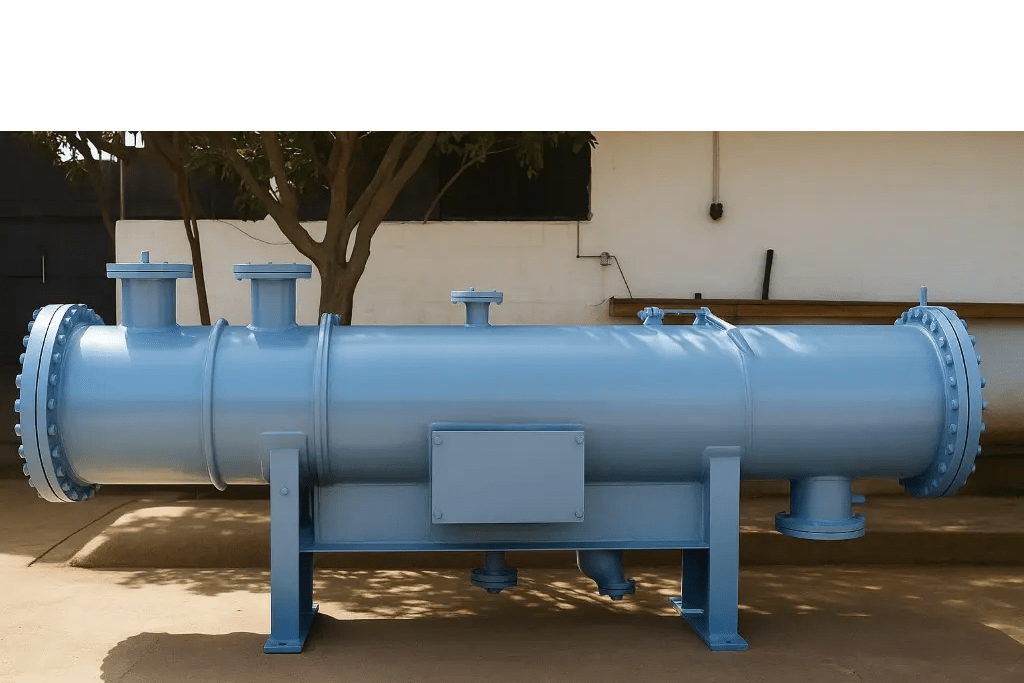

A surface condenser is a type of heat exchanger used primarily in steam power plants to condense exhaust steam from turbines into water (condensate) for reuse in the boiler. It operates by transferring heat from the steam to a cooling medium (usually water or air) without direct contact between the two fluids.

Key Features of a Surface Condenser:

- Shell-and-Tube Design – Consists of a large shell containing numerous tubes through which cooling water flows.

- Indirect Contact – Steam passes over the tubes, condenses, and is collected separately from the cooling medium.

- Vacuum Maintenance – Helps improve turbine efficiency by maintaining low back pressure.

- High Heat Transfer Efficiency – Maximizes condensation while minimizing thermal losses.

Working Principle:

- Exhaust steam from the turbine enters the condenser shell.

- Cooling water circulates inside the tubes, absorbing heat from the steam.

- The steam condenses into water (condensate) and is collected at the bottom (hotwell).

- Non-condensable gases (like air) are removed by an air extraction pump to maintain vacuum.

Types of Surface Condensers:

- Downflow Condenser – Steam enters at the top and condenses as it flows downward.

- Central Flow Condenser – Steam flows toward the center, where condensate is extracted.

- Inverted Flow Condenser – Steam enters from the bottom and rises, improving heat transfer.

Advantages:

- Reusable condensate (saves water and energy).

- Higher thermal efficiency compared to jet condensers.

- Maintains low turbine exhaust pressure, improving power output.

Applications:

- Thermal power plants (coal, nuclear, gas).

- Marine propulsion systems (ship steam turbines).

- Industrial processes requiring steam condensation.

Comparison with Jet Condenser:

| Feature | Surface Condenser | Jet Condenser |

| Cooling Method | Indirect (separate fluids) | Direct (mixing) |

| Condensate Reuse | Yes | No (contaminated) |

| Vacuum Efficiency | Better | Lower |

| Maintenance | More complex | Simpler |

Common Issues:

- Tube fouling (scaling, corrosion) reduces efficiency.

- Air leakage affects vacuum levels.

- Cooling water consumption can be high (unless recirculated).