Plate heat exchanger is composed of several key parts, including plates, gaskets, a frame, and inlet/outlet ports. The plates are thin, corrugated metal sheets that facilitate heat transfer between two fluids. Gaskets seal the space between plates, preventing leaks and directing fluid flow. The

Plates:

These are the core components where heat exchange occurs. They are typically made of stainless steel or titanium and are corrugated to increase surface area and turbulence for better heat transfer.

Gaskets:

These seals are placed between the plates to prevent leakage and direct the flow of fluids.

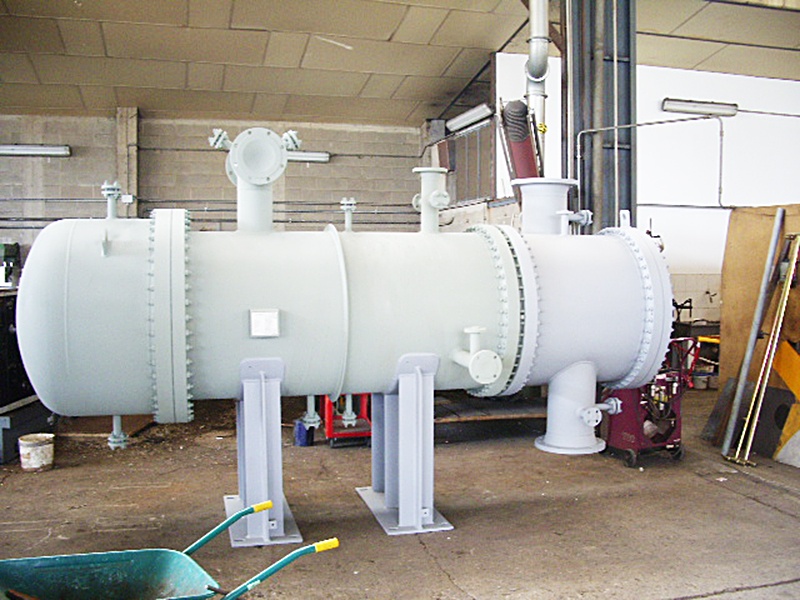

Frame:

The frame provides structural support for the plate pack and other components. It typically consists of a head (or pressure plate), a follower (or another pressure plate), and supporting columns.

Inlet and Outlet Ports:

These are openings where the fluids enter and exit the heat exchanger.

Carrying Bar and Guide Bar: These bars help to support and align the plates during assembly and operation.

Clamping Bolts:

These bolts are used to compress the plate pack, ensuring a tight seal and proper operation.

Fluid Flow Paths: The arrangement of plates and gaskets creates separate channels for each fluid, allowing them to flow in close proximity for efficient heat transfer.