What is an Air Preheater?

An air preheater (APH) is a heat exchanger that recovers waste heat from flue gases and uses it to preheat combustion air entering boilers, furnaces, or kilns. This improves combustion efficiency and reduces fuel consumption by 5-15%.

How Air Preheaters Work

- Hot Flue Gases (250-400°C) exit the boiler/furnace and pass through the APH.

- Cold Combustion Air (ambient temp) flows in the opposite direction (counter-flow design).

- Heat Transfer occurs through:

- Rotating heat-absorbing elements (regenerative type)

- Stationary tubes/plates (recuperative type)

- Preheated Air (150-300°C) enters the combustion chamber, requiring less fuel to reach ignition temperature.

Types of Air Preheaters

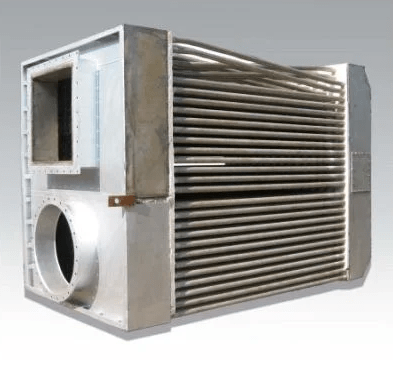

1. Recuperative APH (Tubular)

- Design: Stationary shell-and-tube heat exchanger

- Advantages:

- No moving parts → low maintenance

- Handles high dust loads (cement/steel industries)

- Disadvantages:

- Larger footprint

- Lower efficiency than regenerative types

2. Regenerative APH (Ljungström/Rotary)

- Design: Rotating matrix absorbs/releases heat

- Advantages:

- Compact design

- Higher efficiency (up to 90% heat recovery)

- Disadvantages:

- Air leakage risk

- Requires maintenance of rotating parts

3. Plate-Type APH

- Design: Stacked steel plates create alternating gas/air passages

- Best For:

- Medium-temperature applications

- Corrosive flue gases (with coated plates)

4. Heat Pipe APH

- Design: Sealed pipes with evaporating/condensing fluid

- Advantages:

- No cross-contamination between air/flue gas

- Passive operation (no moving parts)

Key Benefits

Design Considerations

| Factor | Importance |

| Flue Gas Temperature | Determines heat recovery potential |

| Air Leakage | Critical for rotary designs (seal quality) |

| Corrosion Resistance | Stainless steel for acidic flue gases |

| Fouling Potential | Soot/ash buildup reduces efficiency |

| Pressure Drop | Impacts fan power consumption |

Top Applications

- Power Plants – Boiler efficiency improvement

- Cement Kilns – Preheating secondary/tertiary air

- Steel Industry – Blast furnace air heating

Chemical Plants – Process heating optimization