List of parts in Water cooled oil cooler

These are the essential parts that directly facilitate the heat transfer.

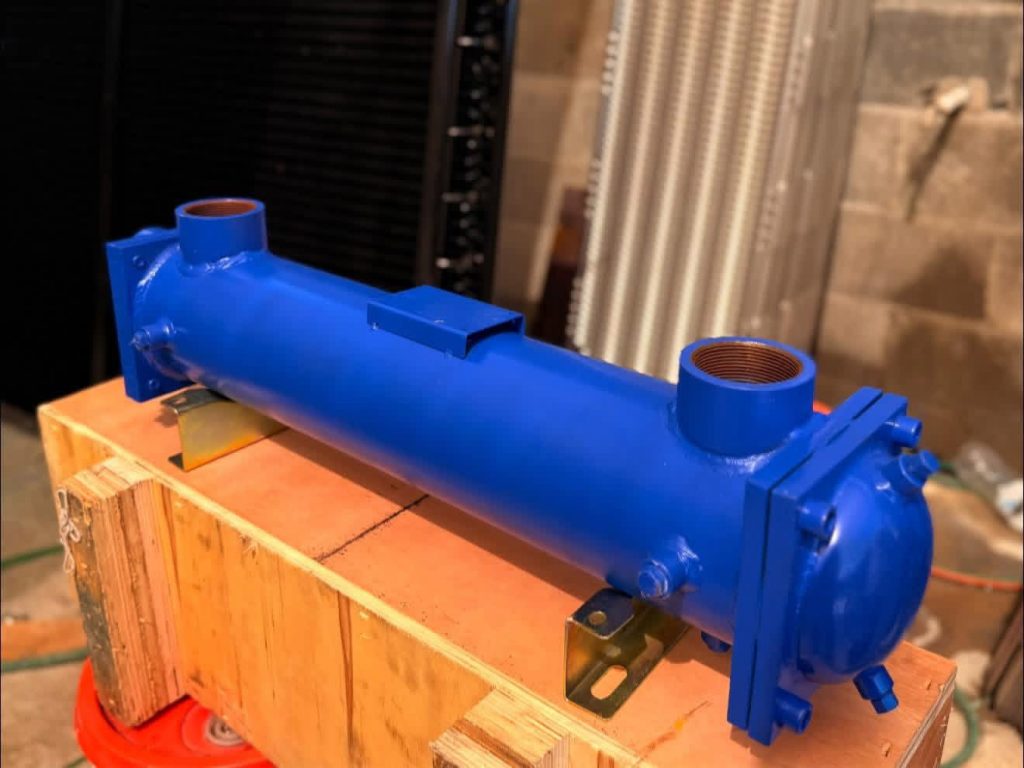

- Shell: The large, outer pressure vessel that contains the tube bundle. The shell-side fluid (typically the oil) flows around the outside of the tubes.

- Tube Bundle: The core assembly inside the shell, consisting of:

- Tubes: A series of metal tubes (often made of copper, brass, stainless steel, or admiralty brass) through which the coolant (water or water-glycol mix) flows. Heat is transferred through the tube walls.

- Baffles: Perforated plates placed inside the shell that support the tubes and force the shell-side fluid to flow across the tubes in a specific pattern. This increases turbulence and heat transfer efficiency.

- Tube Sheets: Thick plates at either end of the shell where the tubes are securely mounted (often expanded or welded). They create a pressure boundary between the shell side and the tube side.

- End Caps / Heads: These are mounted to the tube sheets and direct the tube-side fluid (coolant) through the tubes. There are several types:

- Fixed Head: Simple end caps.

- Removable Head: Allows for easy cleaning and inspection of the tube side without removing the entire unit from the piping.

- Bonnet: A single-pass head.

- Channel: A multi-pass head with partitions to force the coolant back and forth through the tube bundle multiple times for higher efficiency.

Connections & Fittings

These parts allow the cooler to be integrated into the larger system.

- Oil Inlet Port: The connection where hot oil enters the shell side of the cooler.

- Oil Outlet Port: The connection where cooled oil exits the shell side.

- Water Inlet Port: The connection where cool coolant enters the tube side.

- Water Outlet Port: The connection where warmed coolant exits the tube side.

- Drain Plugs: Tapped holes, usually on the shell and heads, to allow for complete drainage of fluids for maintenance or winterization.

- Vent Plugs / Valves: Small fittings at the highest points on the heads and shell to allow air to escape during filling, preventing air locks which reduce efficiency.