How Does a Marine Oil Cooler Work? (The Standard Design)

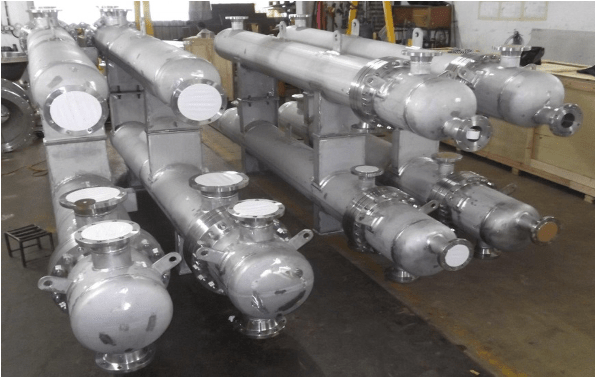

The most common type is the Shell and Tube Heat Exchanger. Here’s how it works:

The Components:

- Shell: A large cylindrical outer vessel.

- Tubes: A bundle of tubes running through the inside of the shell.

- Tube Plates: End plates that seal the tube bundle into the shell.

- Cooling Fluids:

- Tube Side (Inside the Tubes): Seawater is pumped through the tubes. It is kept contained within the tubes because it is corrosive and prone to fouling.

- Shell Side (Outside the Tubes): Hot Oil from the engine or gearbox is pumped into the shell and flows around the outside of the tubes.

The Process:

- Hot Oil In: Oil, heated by the engine (reaching ~65-75°C / ~150-167°F), enters the shell of the cooler.

- Cold Seawater In: Cold seawater is pumped through the tubes.

- Heat Exchange: Heat from the hot oil transfers through the walls of the tubes into the cooler seawater.

- Cooled Oil Out: The oil, now cooled to its ideal temperature (~45-55°C / ~113-131°F), exits the shell and is pumped back to the engine.

- Warm Water Out: The now-warm seawater is discharged overboard.

A thermostatic valve (or bypass valve) automatically regulates the flow of oil either through the cooler or around it to maintain a perfectly consistent oil temperature.