Cleaning Procedures

A. Cleaning an Air-Cooled Oil Cooler (Exterior Fins)

Goal: Remove dirt, bugs, and debris to restore airflow.

- Remove the Cooler (Recommended): For a thorough clean, carefully remove the cooler from its mounting. This allows access to all sides.

- Dry Cleaning: Use compressed air (wear safety glasses!) or a soft bristle brush to loosen and blow out debris. Crucial: Always blow the air in the opposite direction of normal airflow (i.e., from the back side towards the front) to prevent embedding debris deeper into the fins.

- Wet Cleaning:

- Apply a dedicated radiator or coil cleaner (or a mild detergent solution with warm water).

- Let the cleaner soak for the time specified on the product to dissolve stubborn grime.

- Gently rinse with a low-pressure stream of water, again from the back towards the front. Never use a high-pressure washer, as it will bend the delicate fins and cause more harm than good.

- Straighten Fins: Use a fin comb (available at automotive stores) to carefully straighten any bent fins and restore proper airflow channels.

- Reinstall: Once completely dry, reinstall the cooler, ensuring all connections are tight.

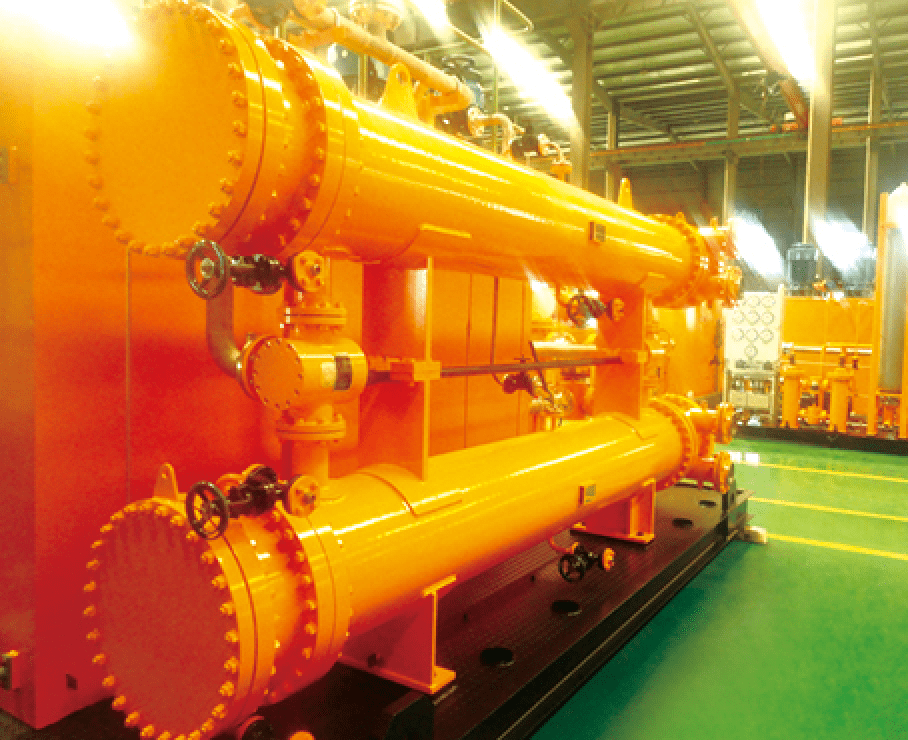

B. Cleaning a Water-Cooled Oil Cooler (Interior Passages)

This is more complex and often requires professional cleaning. The goal is to dissolve sludge, varnish, and carbon deposits.

- Removal: The cooler must be removed from the vehicle/machine.

- Flushing with Solvent:

- Use a hydrocarbon-based solvent or a dedicated oil cooler cleaner.

- Plug one inlet/outlet and fill the cooler with the solvent. Let it soak according to the product’s instructions.

- Agitate the cooler vigorously and drain the solvent. Repeat until the solvent drains clear.

- Final Flushing:

- Perform a final flush with a light, clean oil or a fast-evaporating solvent to remove any residue from the cleaning agent.

- Ensure the cooler is completely dry internally before reinstalling. Use compressed air to blow out all moisture.