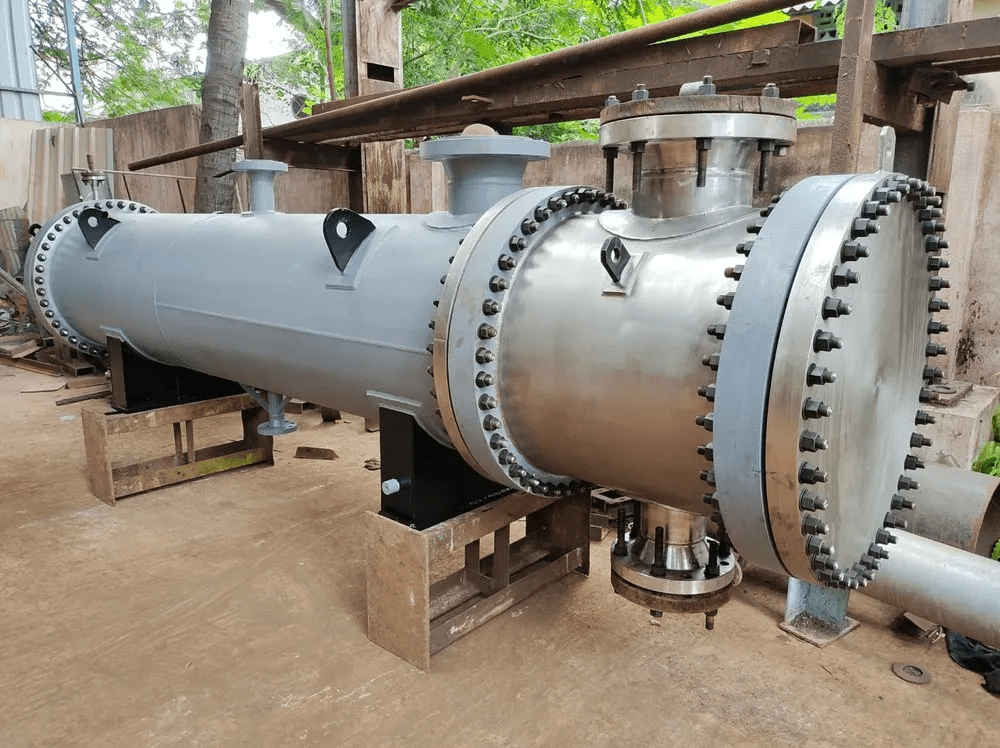

Types of Shell and Tube Heat Exchanger

The types of Shell and Tube Heat Exchangers (STHE) are primarily classified based on their construction design, which is largely determined by how they handle thermal stress and the desired flow path. The rear head and baffle design are key differentiators.

1. Classification by Rear Head Type (Handling Thermal Expansion)

This is the most common classification system, often referred to by the TEMA designation (Tubular Exchanger Manufacturers Association).

A. Fixed Tube Sheet (TEMA L and M)

- Design: The tube sheet is welded directly to the shell. The tubes are fixed at both ends and cannot expand independently of the shell.

- Advantages:

- Simplest and cheapest construction.

- Allows for a large number of tubes (high surface area).

- Permits mechanical cleaning of the tube interiors.

- Disadvantages:

- Cannot handle large temperature differences between shell and tube side fluids (>50°C), as thermal expansion can stress and damage the welds and tubes.

- Shell side cleaning is very difficult (only chemical cleaning is possible).

- Use Case: Applications where the operating temperatures are similar and the shell-side fluid is clean and non-fouling.

B. U-Tube (TEMA U)

- Design: The tube bundle is made of continuous tubes bent into a “U” shape. Both ends of the tubes are fixed to a single tube sheet.

- Advantages:

- Excellent for thermal expansion. The U-bends allow the tubes to expand and contract freely, eliminating thermal stress.

- The tube bundle can be removed for cleaning and inspection.

- Disadvantages:

- Mechanical cleaning of the tube interiors is difficult or impossible due to the tight U-bends.

- Tube wall thickness at the bend can vary, and tubes are harder to replace (inner rows are inaccessible).

- Use Case: High-temperature applications (e.g., heat recovery, rebollers) and where the tube-side fluid is clean.

C. Floating Head (TEMA S, T, P, W)

- Design: One tube sheet is fixed, while the other end is allowed to “float” within the shell. This allows the tube bundle to expand and contract independently of the shell.

- Types:

- Pull-Through Floating Head (TEMA T): The most serviceable design. The entire tube bundle can be “pulled” out of the shell easily for maintenance and cleaning.

- Split-Backing Ring Floating Head (TEMA S): A common and robust design that uses a split backing ring to contain the floating head pressure.

- Advantages:

- Handles high thermal expansion.

- Easy to clean and maintain (both shell and tube side).

- Tubes can be replaced easily.

- Disadvantages:

- Most complex and expensive design.

- More internal gaskets and seals, which can be potential leak points.

- Use Case: The most versatile type. Used for large temperature differences and fouling fluids requiring frequent cleaning.

. Classification by Service/Function

- Single-Pass: Fluid flows through all tubes once.

- Multi-Pass: Baffles in the headers force the tube-side fluid to flow through the tube bundle multiple times (e.g., 2-pass, 4-pass). This increases velocity and improves heat transfer coefficient.

- Condenser: Designed to condense a vapor (e.g., steam) on either the shell or tube side. Often has a vent for non-condensable gases.

- Reboiler: Attached to a distillation column to provide the heat for vaporization. Types include Kettle Reboiler (TEMA K) and Thermosyphon Reboiler.

3. Classification by Shell-Side Flow / Baffle Type

Baffle design dictates how the shell-side fluid flows across the tubes.

- Segmental Baffles (Most Common): Plate with a segment cut away (usually ~25%). Forces fluid to flow in a zig-zag (window-flow) pattern across the tube bundle. Excellent for heat transfer but creates higher pressure drop.

- Disc and Doughnut Baffles: Concentric baffles that create a more linear flow path. Lower pressure drop but less efficient heat transfer.

- Orifice Baffles: Perforated plates that the tubes pass through. Fluid flows through the holes parallel to the tubes.

- Rod Baffles: Uses rods instead of plates to support tubes. Creates parallel flow with very low pressure drop and minimizes vibration.

| Type | TEMA Class | Key Feature | Advantages | Disadvantages |

| Fixed Tube Sheet | L, M, N | Tube sheets welded to shell | Low cost, Simple, Large tube count | No thermal expansion, Hard shell-side cleaning |

| U-Tube | U | Tubes bent into a U-shape | Handles thermal expansion, Removable bundle | Hard tube-side cleaning, Hard to replace inner tubes |

| Floating Head | S, T, P, W | One tube sheet is free to move | Handles thermal expansion, Easy cleaning & maintenance | High cost, Complex design, Potential leaks |