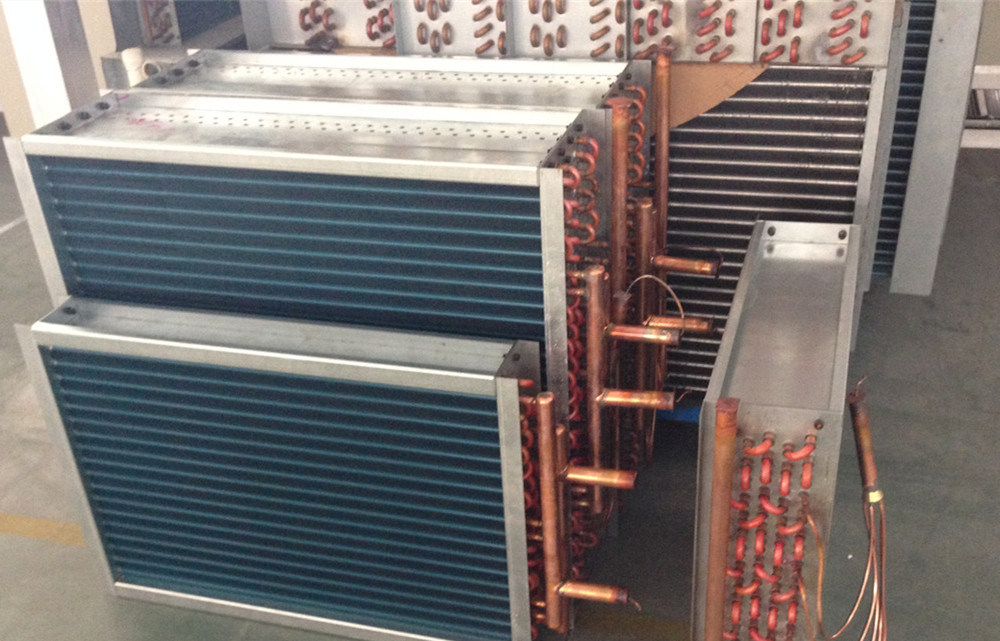

A finned tube heat exchanger is a device that enhances heat transfer between two fluids by using tubes with external fins. These fins increase the surface area of the tube, allowing for a faster and more efficient exchange of heat, particularly when one of the fluids is air or gas.

Here’s a more detailed explanation:

Key Features and Function:

Fins:

The primary feature of these exchangers is the presence of fins attached to the exterior of the tubes. These fins can be made of various materials like aluminum or copper and can have different shapes (e.g., flat, helical, L-shaped).

Enhanced Heat Transfer:

The fins significantly increase the surface area exposed to the surrounding fluid (typically air or gas), which accelerates the rate of heat transfer.

Applications:

Finned tube heat exchangers are widely used in various applications, including HVAC systems, refrigeration, power plants, and industrial processes. They are particularly effective when one of the fluids involved has a lower heat transfer coefficient, such as air.

Efficiency:

The enhanced heat transfer capabilities of finned tubes lead to increased efficiency, energy savings, and reduced environmental impact.

Design Considerations:

The design of finned tubes, including the shape and spacing of fins, is optimized for specific applications and operating conditions.

Materials:

Materials like aluminum, copper, and steel are commonly used for finned tubes, taking into account factors like heat conductivity, corrosion resistance, and cost.