Dry Fluid Cooler vs. Cooling Tower vs. Fluid Cooler

This is a common point of confusion. Here’s the breakdown:

| Feature | Dry Fluid Cooler | Evaporative (Open) Cooling Tower | Fluid Cooler (Closed-Circuit Cooling Tower) |

| Heat Transfer Method | Sensible Only (air cools fluid) | Latent (Evaporative) (water evaporates) | Sensible + Latent (Hybrid) |

| Process Fluid Loop | Closed. Fluid never exposed to air. | Open. Water is sprayed and exposed to air. | Closed. Process fluid is in a coil, separate from spray water. |

| Water Consumption | Zero (after initial fill) | Very High (due to evaporation and blowdown) | Moderate (for the external evaporative spray) |

| Approach Temperature | Higher (less efficient in high temps) | Lower (more efficient) | Varies (can approach wet-bulb temp in hybrid mode) |

| Risk of Legionella | None | Yes (requires water treatment) | Low (only in the separate spray system) |

| Maintenance | Low (clean coils periodically) | High (water treatment, biocide, cleaning) | Moderate (clean coils and maintain spray system) |

Simple Analogy:

- Dry Cooler: Blowing on a hot bowl of soup to cool it down.

- Cooling Tower: Leaving the soup out; it cools primarily by evaporation.

- Fluid Cooler: Putting the soup in a sealed plastic bag and then running cold water over the bag.

Advantages and Disadvantages

Advantages:

- Water Savings: The biggest advantage. Uses no water, making it ideal for arid regions or places with strict water usage regulations.

- Low Maintenance: No water treatment, chemical costs, or concerns about scaling, algae, and biological growth inside the core.

- Clean Process: The closed loop keeps the process fluid clean and free of contaminants, which is critical for sensitive systems.

- Environmental Safety: Eliminates the risk of Legionnaires’ disease associated with open evaporative systems.

- Ease of Installation: Generally simpler to install as there is no connection to a water supply or sewer for blowdown.

Disadvantages:

- Lower Efficiency in High Ambients: Since it can only cool the fluid to a temperature above the ambient dry-bulb temperature (typically within 10-20°F or 5-10°C), it is less effective on very hot days compared to a cooling tower, which can cool to near the ambient wet-bulb temperature (which is always lower).

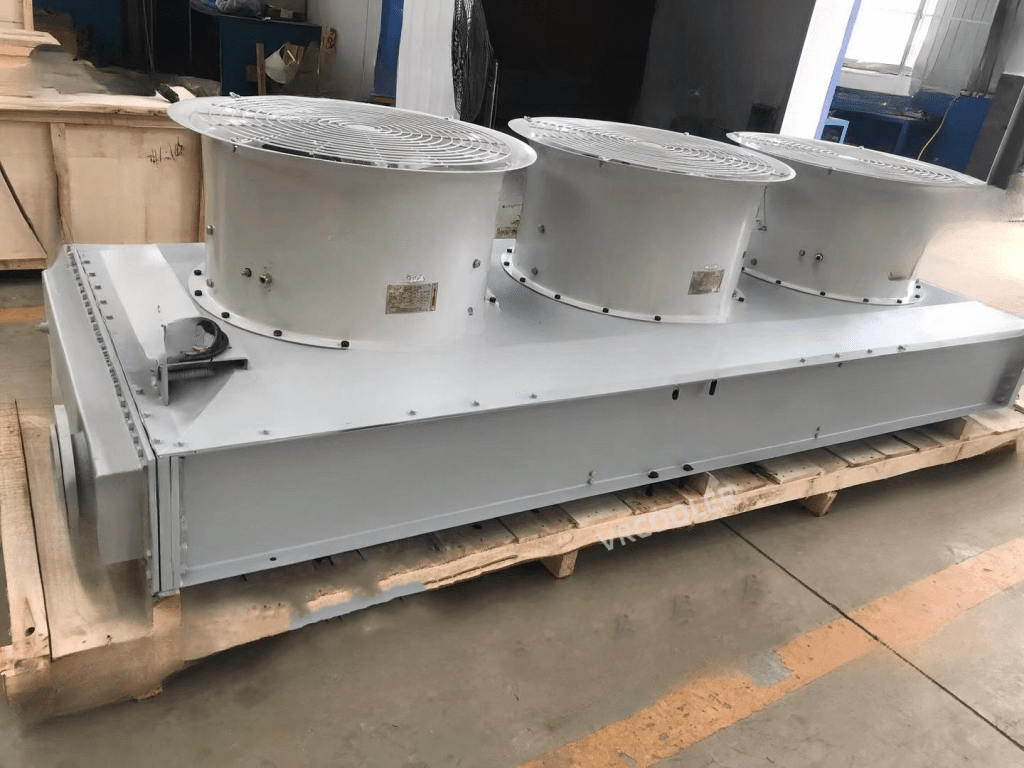

- Larger Physical Size: To achieve similar cooling capacity as an evaporative unit, a dry cooler requires a larger heat exchanger surface area and bigger fans, meaning a larger footprint.

- Higher Energy Consumption: The fans require more energy to move the large volumes of air needed for sensible cooling compared to the pumps of a similarly sized cooling tower.

Common Applications

Dry fluid coolers are used anywhere where water conservation, fluid purity, or environmental safety is a priority:

- Industrial Process Cooling: Cooling hydraulic oil, lubricants, plating tanks, injection molding machines, laser tubes, and induction furnaces.

- Power Generation: Cooling the lube oil for turbines and generators in power plants.

- Data Centers: Rejecting heat from server cooling loops in water-scarce regions.

- HVAC Systems: As a heat rejection device for water-cooled chillers in a “water-side economizer” mode.

- Plastic & Food Processing: Where clean process cooling is mandatory.

- Geothermal Heat Rejection: In cooling-dominant buildings with geothermal heat pump systems.