What is Dry Fluid Cooler

A Dry Fluid Cooler (also known as a Dry Cooler or Air Cooled Heat Exchanger) is a device that cools a process fluid (most commonly water or a water-glycol mixture) using ambient air. The key characteristic is that the process fluid never directly contacts the cooling air; it remains contained within a closed-loop coil. This separates it from systems that use evaporation, like cooling towers.

The Core Principle: How It Works

The operation is based on the fundamental principle of sensible heat transfer.

- Hot Process Fluid Enters: The warm fluid from your industrial process, data center, or power plant is pumped into the dry cooler.

- Air is Blown Across Finned Coils: One or more large fans force ambient air across a series of coils or tubes. These tubes have external fins to dramatically increase the surface area available for heat exchange.

- Heat is Transferred: The heat energy from the hot process fluid inside the tubes transfers through the tube walls to the cooler ambient air blowing over the fins. This is purely sensible heat transfer—no mass transfer (evaporation) occurs.

- Cooled Fluid Returns: The now-cooled fluid is pumped back to the process to absorb more heat, and the cycle repeats.

- Warm Air is Exhausted: The air, having absorbed the heat, is exhausted to the atmosphere.

In essence, it works exactly like a car radiator, but on a much larger industrial scale.

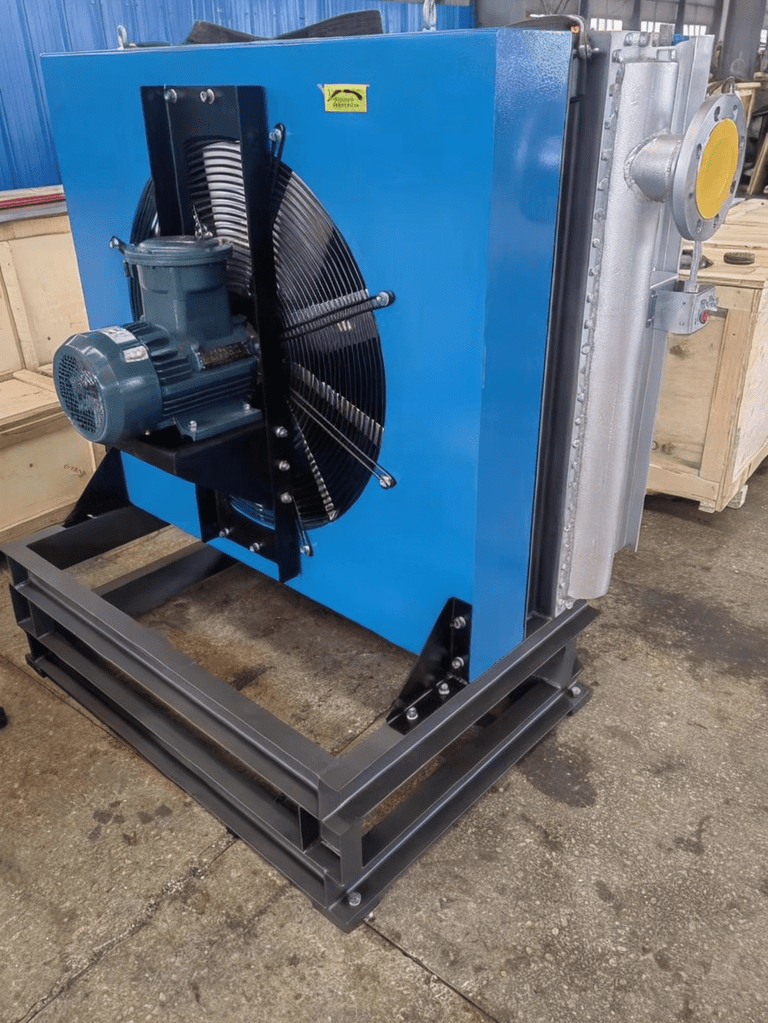

Key Features and Components

- Finned-Tube Heat Exchanger Core: The heart of the system. Tubes carry the fluid, and fins maximize heat transfer to the air.

- Axial Fans: Large, high-volume fans that move the air. They are often arranged in banks and can be controlled by variable frequency drives (VFDs) to adjust cooling capacity based on demand and ambient temperature.

- Pump Package: While sometimes external, many dry coolers have an integrated pump to circulate the process fluid.

- Closed-Loop Circuit: The process fluid is sealed inside, protecting it from contamination, scale, and corrosion. This also means there is no water consumption or “drift” (water droplets lost to the wind).