he role of a cooling tower in power generation is absolutely fundamental and can be summarized in one core concept: It is the primary device that enables the thermodynamic cycle to repeat continuously, thereby allowing for constant electricity production.

In a thermal power plant (coal, natural gas, nuclear, geothermal, etc.), the cooling tower is not an optional accessory; it is a critical component of the heat rejection system.

To understand the cooling tower’s role, you must first understand the basic power plant cycle:

- Boiler: Water is turned into high-pressure steam using heat from fuel (coal, gas) or a nuclear reaction.

- Turbine: The high-pressure steam expands through a turbine, spinning it and connected to a generator to produce electricity.

- Condenser: The now low-pressure, low-energy steam exiting the turbine must be converted back into water (condensate) so it can be pumped back to the boiler to start the cycle again.

The cooling tower’s entire purpose is to serve the Condenser.

The Specific Role of the Cooling Tower

The condenser is a giant heat exchanger. Inside it, the cool water from the cooling tower absorbs heat from the steam, causing the steam to condense back into liquid water.

The cooling tower’s job is to take this now-hot cooling water and reject its waste heat to the atmosphere, cooling it down so it can be reused in the condenser. This creates a continuous, closed-loop cycle for the cooling water.

In essence: The cooling tower dumps the “waste heat” from the power generation process into the environment, making the cycle sustainable.

Why is this so Critical?

- Maintains Low Turbine Back-Pressure: For the steam turbine to operate efficiently, the pressure on its exhaust side (in the condenser) must be extremely low—almost a vacuum. When the cooling water effectively cools the steam, it creates this vacuum. If the cooling water is too warm, the steam won’t condense properly, pressure will rise, and the turbine has to work harder to push against this pressure, drastically reducing efficiency and power output.

- Enables Cycle Repetition: Without condensing the steam back to water, you cannot efficiently pump it back into the high-pressure boiler. The cycle would stop. The cooling tower makes the power plant a closed-loop system for the working fluid (water/steam).

Water Conservation: A power plant produces a massive amount of waste heat. Without a cooling tower, the only option would be “once-through cooling,” where water is taken from a river, lake, or ocean, passed through the condenser, and returned much warmer to the source. This method

- Consumes vast amounts of water.

- Causes thermal pollution, harming aquatic ecosystems.

- Cooling towers (especially wet towers) recycle over 95% of the cooling water, only losing a small portion to evaporation, making power generation possible in areas with limited water resources.

Types of Cooling Towers in Power Generation

Power plants use the largest cooling towers in the world, often seen as iconic hyperbolic-shaped natural draft towers.

- Natural Draft Cooling Towers:

- How they work: They use a very tall hyperbolic chimney. The warm, moist air inside the tower is less dense than the cooler, drier air outside. This density difference creates a natural buoyancy, constantly pulling cold air in at the bottom and pushing hot air out at the top. No fans are required.

- Use Case: Extremely large power plants (especially nuclear) where their immense size and the massive heat load make the construction of the tall shell cost-effective over the long term due to zero fan energy consumption.

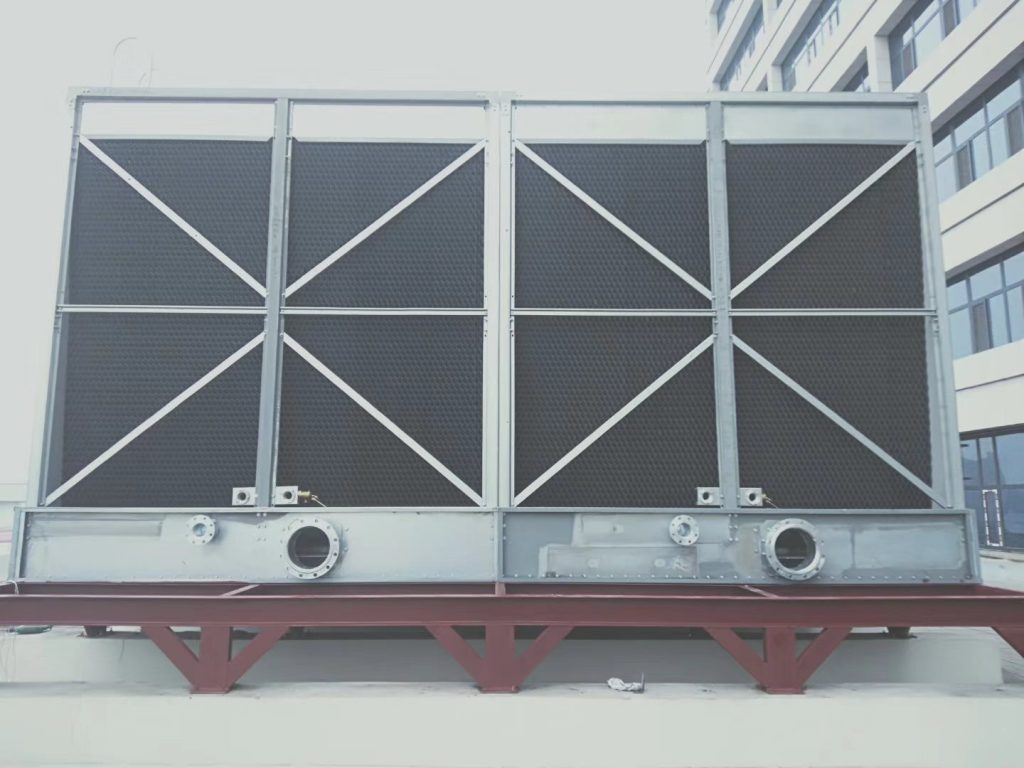

- Mechanical Draft Cooling Towers (Crossflow & Counterflow):

- How they work: Use large fans to force or induce air flow. They are more common than natural draft towers and can be built in multi-cell configurations.

- Use Case: Many coal and gas-fired plants. They are more flexible and have a lower initial construction height/cost than natural draft towers.