What is Air Cooled Heat Exchanger?

An Air Cooled Heat Exchanger (ACHE) is a device that rejects heat from a fluid or gas directly to the ambient air. It operates on the principle of sensible heat transfer, where one or more fans force or induce air flow across a bundle of finned tubes, through which the hot process fluid is flowing. The heat is transferred from the fluid, through the tube walls and fins, and into the air stream, which is then discharged to the atmosphere.

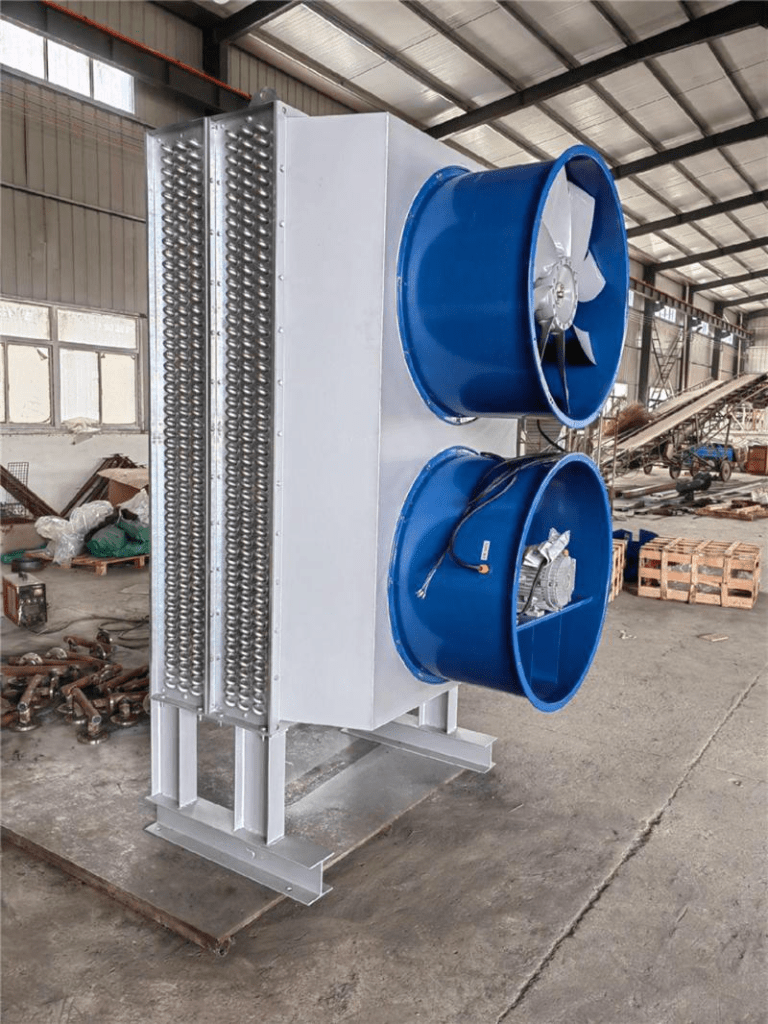

Components and How They Work

To understand how an ACHE functions, let’s break down its main parts:

- Finned Tube Bundle: This is the heart of the exchanger.

- Tubes: The hot process fluid flows inside these tubes.

- Fins: These are metal plates (usually aluminum) mechanically or welded onto the outside of the tubes. Fins dramatically increase the surface area for heat transfer because air is a poor conductor of heat compared to water. Without fins, the exchanger would be prohibitively large and inefficient.

- Fans and Drivers:

- Fans: Large, axial-flow fans (like a household ceiling fan, but much larger and more powerful) move massive volumes of air across the finned tube bundle.

- Drivers: The fans are powered by electric motors or, in some cases, hydraulic motors or steam turbines. They often have variable speed controls or adjustable pitch blades to regulate airflow and control the cooling.

- Plenum and Structure:

- Plenum Chamber: This is an enclosed space that directs the air from the fan evenly over the tube bundle, preventing it from bypassing the fins.

- Structure: A sturdy steel frame supports the entire assembly, including the tube bundle, fans, and plenum.

- Headers:

- Located at the ends of the tube bundle, headers are large metal boxes that distribute the process fluid into the many parallel tubes and collect it again after cooling.