Direct Cooling Vs Indirect Cooling

The core difference lies in whether the process fluid being cooled is directly exposed to the atmosphere and the cooling air.

Direct Cooling (Open Circuit)

In a direct cooling system, the fluid that needs to be cooled (typically water) is directly exposed to the cooling air and the atmosphere. It is an open circuit.

How it works:

- Hot water from the process (e.g., a condenser) is pumped to the top of the cooling tower.

- It is then distributed over a fill (a material that creates a large surface area) and allowed to trickle down.

- Air is drawn through the falling water, causing a small portion of the water to evaporate.

- This evaporation removes heat from the remaining water, cooling it significantly.

- The cooled water collects in a basin at the bottom and is pumped back to the process to absorb more heat.

Key Feature: The water that gets cooled is the same water that is being evaporated and exposed to the air.

Analogy: Sweating. Your body cools directly by secreting water (sweat) onto your skin, where it evaporates and cools you down.

Common Example:

- Traditional Evaporative (Wet) Cooling Tower

Advantages:

- High Efficiency: Can cool water to a temperature very close to the ambient wet-bulb temperature, which is the theoretical limit for evaporative cooling.

- Lower Capital Cost: Generally simpler construction and less expensive to install for a given capacity.

Disadvantages:

- Water Contamination: The open circuit exposes water to air, dirt, dust, algae, and other airborne contaminants.

- Water Loss: Significant water is lost through evaporation, drift (water droplets carried away by air), and blowdown (draining concentrated water to control scaling).

- Scale and Corrosion: Minerals in the water become concentrated as pure water evaporates, leading to scaling and increased corrosion potential. Requires rigorous water treatment.

- Legionella Risk: The warm, aerated water is an ideal environment for bacterial growth like Legionella, requiring careful maintenance and biocide treatment.

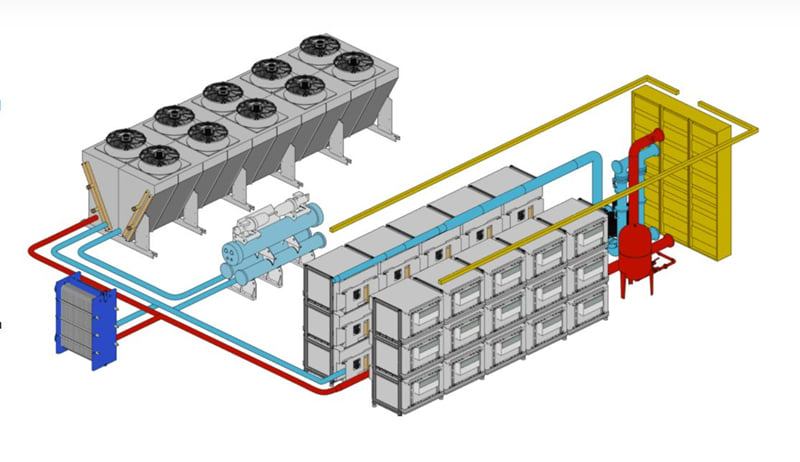

Indirect Cooling (Closed Circuit) In an indirect cooling system, the process fluid that needs to be cooled is never

exposed to the atmosphere. It is contained within a closed circuit. A separate fluid or water stream is used to reject the heat to the atmosphere.

How it works:

- The hot process fluid is pumped through a coil (a heat exchanger), which is sealed from the outside environment.

- In an adiabatic cooler, this coil is sprayed with water and cooled by air. In a dry cooler, it is cooled only by air.

- The heat from the closed-loop fluid is transferred through the coil’s wall to the outside.

- On the outside, water is evaporated and/or air is moved to carry the heat away.

Key Feature: Two separate circuits:

- A primary, closed loop containing the clean process fluid.

- A secondary loop (water or air) that rejects the heat to the atmosphere.

Analogy: The radiator in your car. The engine coolant (a water-glycol mix) flows through a sealed radiator. Air blows across the radiator’s fins, cooling the coolant inside without the coolant ever mixing with the air.

Common Examples:

- Adiabatic Coolers (the best example for this comparison)

- Dry Coolers (100% sensible cooling, no water used)

- Shell and Tube Heat Exchanger connected to a cooling tower.

Advantages:

- System Protection: The primary process loop remains clean and free of scale, corrosion, and biological contaminants. This is critical for cooling sensitive equipment like lasers, MRI machines, or internal building HVAC loops.

Water Conservation: Uses significantly less water than a direct cooling system. In a dry cooler, it uses no water. In an adiabatic cooler, water is only used for pre-cooling air

- during hot periods.

- Lower Operating Costs (Potentially): Reduced chemical water treatment costs and less make-up water pumping.

- No Legionella Risk in Primary Loop: The bacteria cannot grow in the clean, closed loop.

Disadvantages:

- Higher Initial Cost: More complex due to the inclusion of a heat exchanger (coil).

- Slightly Lower Efficiency: The heat must transfer through a barrier (the coil wall), which creates a small temperature difference penalty. It cannot cool the fluid quite as close to the wet-bulb temperature as a direct system can.