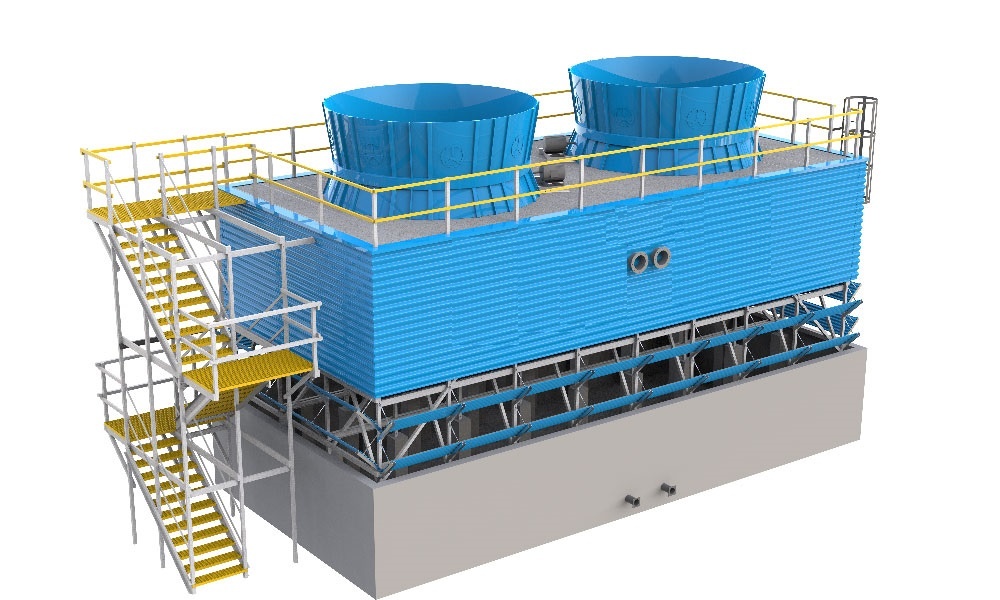

A Pultruded cooling tower refers to a cooling tower constructed using pultruded fiber-reinforced polymer (FRP) composites instead of traditional materials like wood, metal, or conventional molded FRP. Pultrusion is a continuous manufacturing process that produces high-strength, lightweight, and corrosion-resistant profiles, making it an attractive option for cooling tower components.

Key Features of Pultruded Cooling Towers:

- Material Advantages:

- Corrosion Resistance: Unlike steel or wood, pultruded FRP does not rust, rot, or degrade from exposure to water and chemicals.

- High Strength-to-Weight Ratio: Stronger than wood and lighter than steel, reducing structural load.

- Dimensional Stability: Resists warping, swelling, or shrinking in humid/wet conditions.

- UV & Chemical Resistance: Can be formulated with additives to withstand harsh environments.

- Components Made via Pultrusion:

- Structural supports (beams, columns, frames)

- Cooling tower louvers

- Fill media supports

- Fan cylinders & casings

- Drift eliminators

- Benefits Over Traditional Cooling Towers:

- Longer Lifespan: No corrosion or biological degradation.

- Lower Maintenance: No need for painting, coating, or frequent replacements.

- Energy Efficiency: Lightweight materials reduce fan motor load.

- Customizable Designs: Pultruded profiles can be tailored for specific load requirements.

- Applications:

- Industrial cooling towers (power plants, refineries, HVAC systems)

- Evaporative coolers

- Water treatment plants

Comparison with Molded FRP Cooling Towers:

- Pultruded FRP offers better consistency in mechanical properties since it’s a continuous process.

- Molded FRP (hand-layup or filament winding) is better for complex shapes but may have variations in strength.

Challenges:

- Higher initial cost compared to wood or metal (though lifecycle costs are lower).

- Requires expertise in FRP structural design.