Types of Air-Cooled Oil Coolers

Air-cooled oil coolers come in different designs, each suited for specific applications based on cooling efficiency, space constraints, airflow conditions, and industry requirements. Below are the main types:

1. Tube & Fin Oil Coolers

(Most Common Type)

- Design:

- Oil flows through metal tubes (usually aluminum or copper).

- Fins (aluminum/stainless steel) are attached to tubes to increase surface area.

- Advantages:

- Lightweight, cost-effective, and easy to maintain.

- Good for moderate cooling needs.

- Applications:

- Automotive engines & transmissions.

- Industrial hydraulic systems.

- Compressed air systems.

. Plate & Fin Oil Coolers

(Compact & High-Efficiency)

- Design:

- Consists of stacked plates with fins in between.

- Oil flows through channels, while air passes over fins.

- Advantages:

- More surface area than tube-fin coolers → better cooling in a smaller size.

- Handles higher pressures than tube-fin designs.

- Applications:

- Aerospace & aviation systems.

- High-performance vehicles (racing, turbocharged engines).

- Industrial process cooling.

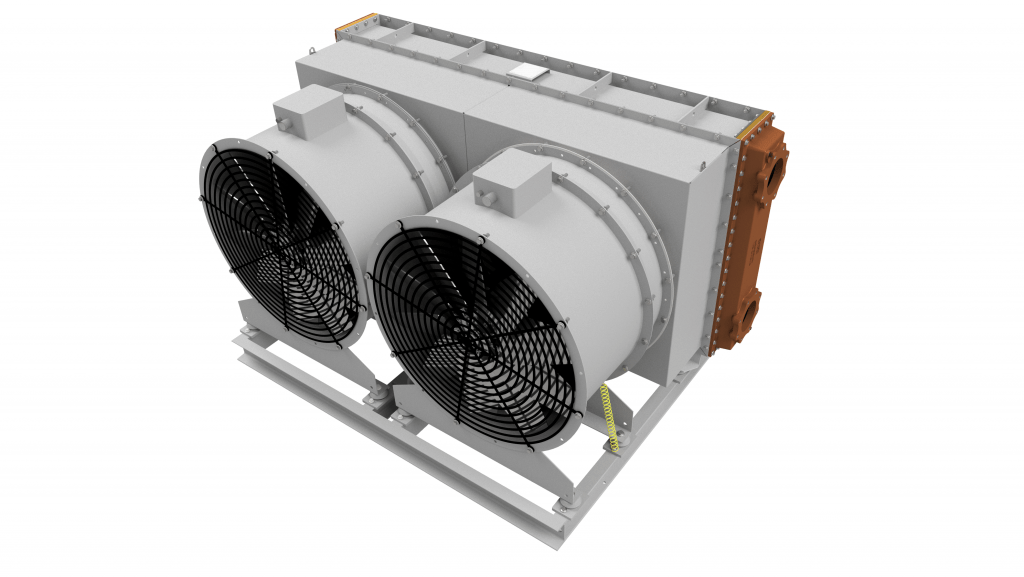

3. Forced-Draft (Fan-Cooled) Oil Coolers

(Active Cooling for High Heat Loads)

- Design:

- Uses an electric or hydraulic fan to force air over fins.

- Can be tube-fin or plate-fin internally.

- Advantages:

- Consistent cooling even at low speeds or stationary operation.

- Can handle very high heat loads.

- Applications:

- Heavy machinery (excavators, mining trucks).

- Power generators & turbines.

- Data centre cooling systems.

4. Natural Draft (Passive) Oil Coolers

(No Fan – Relies on Ambient Airflow)

- Design:

- Depends on natural convection or vehicle/equipment movement for airflow.

- Usually, larger fins to compensate for lower airflow.

- Advantages:

- No power/fan needed → lower maintenance.

- Silent operation.

- Applications:

- Wind turbine gearboxes.

- Some automotive transmissions.

- Solar power systems.

5. Stacked-Plate Oil Coolers

(Heavy-Duty Industrial Use)

- Design:

- Multiple metal plates stacked with oil passages.

- Fins brazed between plates for heat exchange.

- Advantages:

- Extreme durability for high-pressure systems.

- Resistant to vibration & shock.

- Applications:

- Offshore oil rigs.

- Steel & metalworking machinery.

- Military vehicles.

6. Extruded Tube Oil Coolers

(High-Pressure Resistance)

- Design:

- Uses seamless extruded tubes for oil flow.

- Fins are crimped or welded onto tubes.

- Advantages:

- No risk of leaks (ideal for high-pressure hydraulics).

- Long lifespan.

- Applications:

- Construction equipment (cranes, bulldozers).

- Mining machinery.

Comparison Table

| Type | Cooling Efficiency | Best For | Maintenance |

| Tube & Fin | Moderate | Automotive, general industry | Low |

| Plate & Fin | High | Aerospace, racing | Medium |

| Forced-Draft (Fan) | Very High | Heavy machinery, generators | Medium-High |

| Natural Draft | Low-Medium | Wind turbines, passive cooling | Very Low |

| Stacked-Plate | High | Offshore, military | Low |

| Extruded Tube | Moderate-High | Mining, construction | Low |

How to Choose the Right Type?

- Cooling Needs:

- High heat loads → Forced-draft or plate-fin.

- Moderate needs → Tube-fin or extruded tube.

- Environment:

- Harsh conditions → Stainless steel stacked-plate.

- Space constraints → Plate-fin.

- Power Availability:

- No electricity → Natural draft.

Active cooling → Forced-draft.