In industrial cooling applications, indirect cooling towers are gaining popularity for their ability to deliver efficient heat rejection while protecting process fluids from contamination. At the heart of these systems lies the cooling coil — a critical component that ensures effective thermal exchange and long service life. Understanding the role, design, and benefits of a coil in an indirect cooling tower is essential for maximizing performance and operational efficiency.

What is a Coil in an Indirect Cooling Tower?

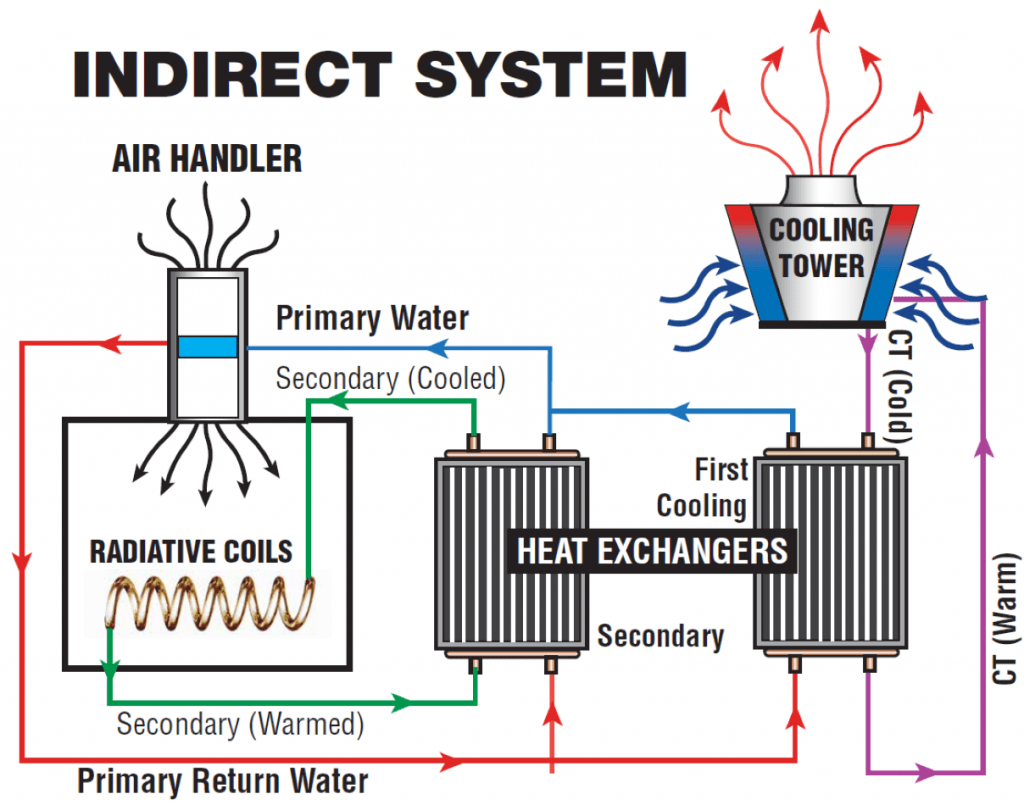

coil in an indirect cooling tower is a heat exchanger, usually made of copper, stainless steel, or galvanized steel tubing, placed inside the tower. Process water or another working fluid flows inside the coil, while ambient air and spray water circulate outside the coil to remove heat. This design eliminates direct contact between process fluid and cooling water, preventing contamination.

How It Works

- Process Fluid Inside the Coil

The coil carries the closed-loop process fluid, such as chilled water, glycol mixture, or industrial fluids. - Spray Water Over the Coil

The tower’s spray nozzles distribute water over the coil surface. - Evaporative Cooling Effect

Air drawn through the tower evaporates a portion of the spray water, extracting heat from the coil. - Heat Transfer

The temperature of the process fluid is lowered before it returns to the system.

Advantages of Using a Coil in an Indirect Cooling Tower

Reduced Contamination

- No direct exposure of process fluid to atmospheric impurities.

Lower Maintenance

- Process side remains clean, reducing filtration requirements.

Energy Efficiency

- Enhanced thermal performance reduces compressor load in HVAC or process cooling systems.

Extended Equipment Life

- Protection from scaling, fouling, and biological growth.

Versatility

- Suitable for HVAC, data centers, food processing, pharmaceuticals, and chemical plants.

Coil Design Considerations

- Material Selection: Stainless steel (SS 304/316) for corrosion resistance, copper for high conductivity, or galvanized steel for cost-effectiveness.

- Tube Diameter & Wall Thickness: To optimize heat transfer and pressure drop.

- Coil Surface Area: Larger surface area increases cooling capacity.

- Corrosion Protection: Epoxy coating or hot-dip galvanization for harsh environments.

Maintenance Tips

- Periodic coil inspection for scaling or corrosion.

- Cleaning with non-abrasive methods like soft brushing or chemical descaling.

- Ensuring spray nozzles are not clogged for uniform water distribution.

- Maintaining proper water chemistry to prevent scaling and fouling.

The coil in an indirect cooling tower is the backbone of efficient closed-loop cooling. Selecting the right coil material, design, and maintenance strategy not only ensures optimal performance but also extends the lifespan of the entire cooling system. For industries where fluid purity and operational reliability are critical, investing in a well-designed coil system is a smart move.