Air-Cooled Heat Exchangers (ACHEs) in Marine Applications

Air-cooled heat exchangers are widely used in marine and offshore systems where seawater corrosion, space constraints, and maintenance challenges make water-cooled systems less desirable. They provide reliable cooling for ship engines, HVAC systems, power generation, and offshore platforms while eliminating dependency on seawater cooling.

1. Working Principle in Marine Systems

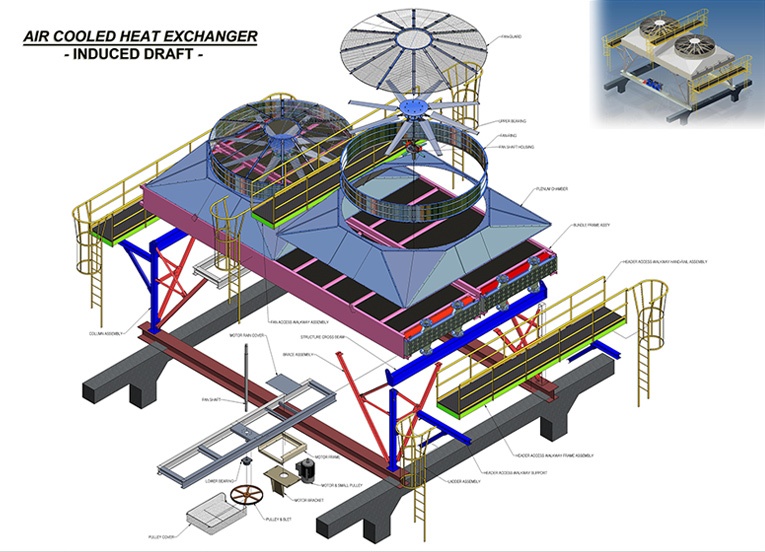

- Heat transfer from hot fluids (lubricating oil, fuel, refrigerant, or freshwater) to ambient air via finned tubes.

- Forced-draft or induced-draft fans drive airflow across the tubes.

- Closed-loop cooling prevents seawater contamination and corrosion.

2. Key Applications in Marine & Offshore

A. Marine Engine Cooling

- Lube oil & jacket water cooling for main and auxiliary diesel engines.

- Charge air cooling (after turbochargers) to improve engine efficiency.

- Reduces fouling & corrosion compared to seawater-cooled systems.

B. HVAC & Refrigeration Systems

- Condensers for marine AC units (reduces seawater use).

- Refrigerant cooling in reefer containers and cold storage.

C. Hydraulic & Power Systems

- Cooling hydraulic oil in winches, cranes, and thrusters.

- Transformer & generator cooling on ships and offshore platforms.

D. Offshore Oil & Gas Platforms

- Process cooling for gas compression and separation.

- Closed-loop glycol cooling to avoid seawater contamination.

E. Naval & Submarine Applications

- Stealth operations (no seawater discharge, reducing thermal signatures).

- Reduced maintenance in harsh saltwater environments.

3. Advantages in Marine Environments

No Seawater Dependency – Eliminates corrosion, biofouling, and scaling.

Lower Maintenance – No need for seawater pumps, filters, or chemical treatment.

Compact & Modular – Can be installed in tight engine rooms or decks.

Environmentally Friendly – No risk of oil or chemical leaks into the sea.

Flexible Placement – Can be mounted horizontally or vertically.

4. Challenges & Limitations

Salt & Moisture Corrosion – Requires stainless steel, aluminum, or coated fins.

Space Constraints – May need compact designs for tight engine rooms.

High Ambient Temperatures – Reduced efficiency in tropical climates.

Vibration & Shock Resistance – Must withstand rough sea conditions.

5. Design Considerations for Marine ACHEs

- Corrosion-Resistant Materials (316L stainless steel, cupronickel, or coated aluminum fins).

- Marine-Grade Fans (salt-resistant coatings, waterproof motors).

- Vibration Dampeners – To handle ship movements and engine vibrations.

- Sea-Salt Filtration – Optional self-cleaning filters for fan intakes.

- Modular & Lightweight Construction – For easier installation and maintenance.

6. Maintenance Best Practices

- Regular Cleaning – Remove salt deposits and debris from fins.

- Inspect Fan Motors & Bearings – Check for moisture ingress.

- Corrosion Checks – Look for rust on fins, tubes, and structural supports.

- Lubricate Moving Parts – Ensure smooth fan operation.

7. Future Trends in Marine ACHEs

- Hybrid Cooling Systems – Combining air-cooled with minimal seawater backup.

- Smart Monitoring – IoT sensors for predictive maintenance.

- Lightweight Composite Materials – Reducing weight for fuel efficiency.

- Anti-Fouling Coatings – Nano-coatings to repel salt and moisture.

Air-cooled heat exchangers are a reliable, low-maintenance solution for marine and offshore cooling needs. They eliminate seawater corrosion risks, reduce maintenance costs, and comply with environmental regulations. While they require careful material selection and placement, their benefits make them ideal for ships, oil rigs, and naval vessels.