Air-Cooled Steam Condensers (ACSCs) in Power Plants & Industrial Systems

Air-cooled steam condensers (ACSCs) are specialized heat exchangers that convert exhaust steam from turbines back into water using ambient air cooling instead of water-cooled systems. They’re increasingly important in power generation and industrial processes where water conservation is critical.

1. Working Principle

- Steam Condensation: Low-pressure exhaust steam from turbines flows through finned tubes

- Air Cooling: Large fans force/pull ambient air across tube bundles

- Condensate Collection: Condensed water returns to the feedwater system

- Non-condensable Gas Removal: Vacuum system maintains proper pressure

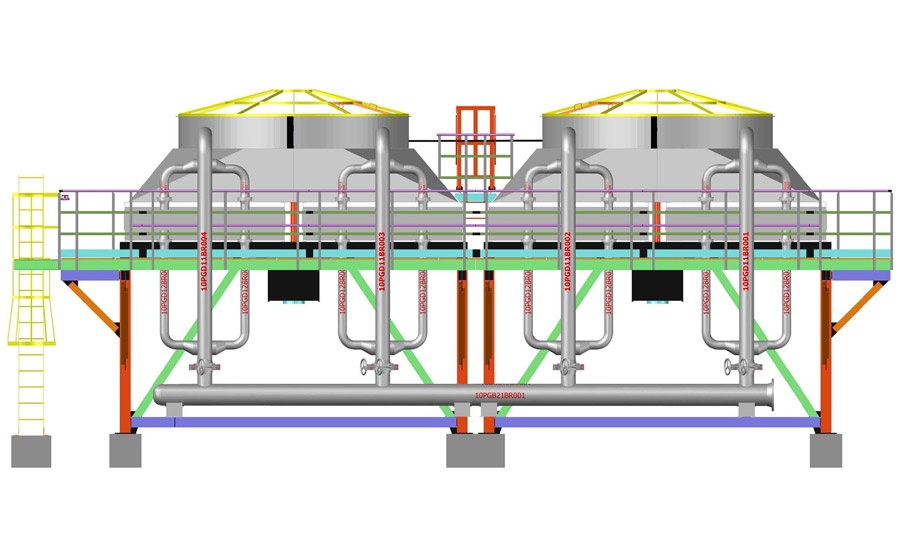

2. Key Components

| Component | Function |

| Tube Bundles | Finned tubes for steam condensation |

| Axial Fans | Provide cooling airflow (forced/induced draft) |

| Steam Ducting | Distributes steam from turbine exhaust |

| Condensate Tank | Collects condensed water |

| Vacuum System | Maintains sub-atmospheric pressure |

| Air Removal System | Extracts non-condensable gases |

3.

System Configurations

A. Direct Dry Cooling (ACC)

·

Steam condenses directly in

air-cooled tubes

·

Used in most modern power

plants

·

No water consumption

B. Indirect Dry Cooling

(Heller System)

·

Steam condenses in surface

condenser

·

Cooling water loop rejects

heat to air-cooled heat exchangers

·

Lower efficiency but more

stable operation

C. Hybrid Wet/Dry Systems

·

Dry cooling with water spray

augmentation during peak loads

·

Balances water savings with

performance

4. Advantages vs. Water-Cooled Condensers

Zero water consumption – Critical for arid regions

Lower

environmental impact – No thermal pollution or water

discharge

Reduced

permitting – Avoids water rights issues

Flexible siting – Not limited to water sources

Lower

maintenance – No biofouling or scaling

5. Challenges & Limitations

Higher capital cost – Larger footprint and more equipment

Lower

efficiency – Performance varies with ambient temperature

Parasitic

power loss – Fan power reduces net output

Cold

weather issues – Potential freezing in winter

Air

Cooled Heat Exchanger Noise concerns – Large fan arrays

require mitigation

6. Design Considerations

·

Climate analysis – Design for peak summer temperatures

·

Tube layout – A-frame, horizontal, or vertical

configurations

·

Fan selection – Variable frequency drives for efficiency

·

Freeze protection – Tube bundle heating systems

·

Noise control – Low-noise fan designs and barriers

7. Applications

Power Generation

·

Thermal power plants (coal,

gas, biomass)

·

Solar thermal power plants

·

Geothermal plants

Industrial Processes

- Refineries

- Chemical plants

- District heating systems

8. Performance Optimization

- Variable speed fans – Adjust to load and ambient conditions

- Intelligent control systems – Optimize vacuum and fan operation

- Wind shields – Reduce performance degradation from crosswinds

- Advanced fin designs – Improve heat transfer efficiency

9. Maintenance Requirements

- Regular fin cleaning – Maintain airflow and heat transfer

- Fan maintenance – Bearing lubrication and alignment

- Leak detection – Steam and condensate systems

- Winterization – Freeze protection measures

Air-cooled steam condensers provide a water-smart solution for power plants and industrial facilities, particularly in water-scarce regions. While they involve higher initial costs and lower efficiency compared to water-cooled systems, their environmental benefits and operational advantages make them increasingly popular in sustainable energy systems.