Introduction:

Tube enhancement heat exchanger were initially developed to use plain (or smooth) heat transfer surfaces. An Enhanced tube heat exchangers surface has a special surface geometry that provides a higher thermal performance, per unit base surface area than a plain surface. This work presents information of an experimental design on the elements of the tube heat exchanger. In this study, three different fins (plate fin, wavy fin, and compounded fin) were investigated in a wind tunnel.

Process Of Tube Enhancement Heat Exchanger

Tube enhancement heat exchangers coefficient, the pressure drop of the air side, the Colburn factor (j), and fanning friction factor (f) against air velocity (1–3 m/s) and Reynolds number (600–2000) have been discussed. In order to shed light on the fluid flow phenomena, flow visualization was also realized to observe the detailed fluid flow characteristics. The results of the wavy fin to the flat fin show that the pressure drop, heat transfer coefficient, f factor and j factor increase about 10.9–31.9%, 11.8–24.0%, 2.2–27.5% and 0.5–2.7%, respectively. In addition, the results of the compounded fin compared to the flat fin show that the pressure drop, heat transfer coefficient, f factor and j factor increase about 33.5–63.1%, 27.0–45.5%, 6.9–71.1% and 9.4–13.2%, respectively. In summary, this study strongly suggests the use of the compounded fin constructed for heat exchanger.

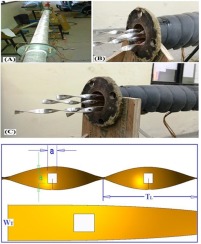

Image Of Tube Enhancement Heat Exchanger:

Advangates Of Tube Enhancement Heat Exchanger

- Higher overall heat transfer coefficient, compared to conventional technologies

- Improved process efficiency based on very low temperature approaches, compared to conventional technologies.

- Condensation or boiling heat transfer can be accommodated in either the tubes or the shell, and the orientation can be horizontal or vertical. You may want to check out the orientation of the heat exchanger in our laboratory. Of course, single phases can be handled as well.

- The pressures and pressure drops can be varied over a wide range.

- Thermal stresses can be accommodated inexpensively.

- There is substantial flexibility regarding materials of construction to accommodate corrosion and other concerns. The shell and the tubes can be made of different materials.

- Extended heat transfer surfaces (fins) can be used to enhance heat transfer.

- Cleaning and repair are relatively straightforward, because the equipment can be dismantled for this purpose.

Features Of Tube Enhancement Heat Excahnger:

- Reduce exchanger sizes

- Allow re-use of existing exchanger shells in revamp or expansion applications

- Reduce exchanger mean temperature differences (MTD’s)

- Minimize cooling water consumption

- Debottleneck summertime limited condensers

- Reduce column operating pressure and increase capacity.

Applications Of Tube Enhancement Heat Exchanger:

In applications of tube enhancement is the objective may be to recover or reject heat, or sterilize, pasteurize, fractionate, distil, concentrate, crystallize, or control a process fluid. Heat exchanger for an ocean thermal energy conversion (OTEC), Heat exchangers for process industries, Sugar factories, diary plants, Chemical industries Heating and cooling in evaporators, Heat exchangers thermal power plants, air- conditioning equipment, refrigerators, radiators for space vehicles, automobiles.