Titanium Tube Heat Exchangers:

Overview:

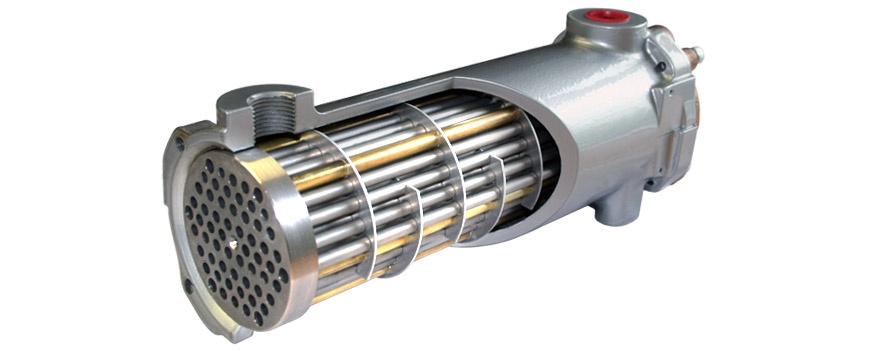

Titanium tube Heat Exchangers are suited for a vast range of chemical environments and conditions, due to a thin, invisible, but extremely protective, surface oxide film (primarily TiO2). Titanium is also recognized for its superior resistance to erosion, erosion-corrosion, cavitations and impingement in flowing, turbulent fluids. Alfa Titanium Shell and Tube Heat Exchanger is fully constructed with pressurized shell and spiral corrugated or smooth inner tube.

Image:

Design And Process:

Titanium tube heat exchangers are typically the ends of each tube are connected to plenums (sometimes called water boxes) through holes in tube sheets. The tubes may be straight or bent in the shape of a U, called U-tubes. In nuclear power plants called pressurized water reactor, large heat exchangers called steam generators are two-phase, titanium tube heat exchangers which typically have U-tubes. They are used to boil water recycled from a surface condenser into steam to drive a turbine to produce power. Titanium tube heat exchanger is named for its two major components round tubes mounted inside a cylindrical shell. The shell cylinder can be fabricated from rolled plate or from piping (up to 24 inch diameters). The tubes are thin-walled tubing produced specifically for use in heat exchangers. Other components include: the channels (heads), tube sheets, baffles, tie rods & spacers, pass partition plates and expansion joint (when required).

Advantages:

These are High efficiency, coefficient up to 10000 W/m2•°C, Heat exchanging capacity 3-7 times traditional equipment’s, Compact configure, occupy small area, one tenth as the traditional equipment’s, Titanium material, endure high temperature, pressure and corruption, Helix screw thread elasticity heat exchange bundle, eliminate the stress, Design flux speed is 5.5m/s, less dirt, Easy clean and maintain, Big flow volume, Compactable, Easy installation and durable.

Features:

These are Titanium construction offers unmatched corrosion resistance, Fully welded construction ensures long-lasting performance, Helically wound tubes improve heat transfer, Large inlet/outlet ports allow for high flow rates with low pressure drop, Mounting brackets included, Fully welded construction, Made from titanium, Helically corrugated tubes offer higher heat transfer efficiency, Suitable for high flow and low pressure drop applications, High flow rates create self-cleaning effect, Resistant against a variety of aggressive fluids, including chlorinated pool water.