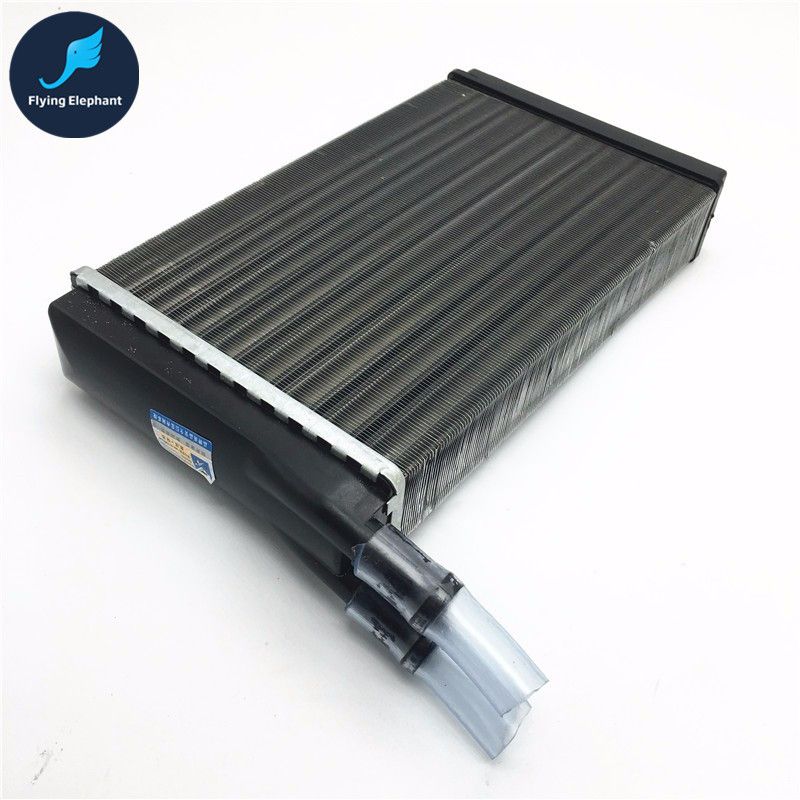

Cooled water Radiators Heat Exchangers:

overview:

Cooled water Radiators heat exchangers are used for cooling internal combustion engines, mainly in automobiles but also in piston-engine aircraft, railway locomotives, motorcycles, stationary generating plant or any similar use of such an engine. Internal combustion engines are often cooled by circulating a liquid called engine coolant through the engine block, where it is heated, then through a radiator where it loses heat to the atmosphere, and then returned to the engine. Engine coolant is usually water-based, but may also be oil. It is common to employ a water pump to force the engine coolant to circulate, and also for an axial fan to force air through the radiator.

Process:

Cooled Water radiators heat exchangers are no plant-wide cooling system, a stand-alone refrigerated chillers is often a good solution for a closed-loop cooling system for your induction heating system and will be an economical solution up to cooling power requirements of 90 kW. Cooled water heat exchangers are available from Ambrell for cooling requirements from 1kW up to 440kW, with the higher power having outdoor evaporator coils. Cooled Water chillers absorb heat from process water and transfer it to a separate water source such as a cooling tower, river, pond, etc. They are generally used for large capacity applications, where the heat generated by an air cooled water chillers creates a problem. They are also considered when a cooling tower is already in place, or where the customer requires optimum efficiency of power consumption.

Image:

Benefits :

- Nontoxic

- Non-flammable

- Aqueous-based

- Superior heat transfer characteristics

- Attractive alternative to glycols and brines.

Features:

- The closed circuit medium is accessible in its entirety

- The heat exchanger is at low level allowing ease of routine maintenance

- Plates are manufactured in 304 or 316 stainless steel

- Facility to add additional plates for extended cooling surface

- Reduce exchanger mean temperature differences (MTD’s)

- Minimize cooling water consumption

- Debottleneck summertime limited condensers

- Reduce column operating pressure and increase capacity.

Applications:

- Liquid-to-liquid

- Cryogenic

- High pressure

- Clean steam generators

- Blow down

- Natural gas heaters

- Vent condensers

- Mechanical seal coolers

- Compressor inter/after coolers

- Supercritical fluid

- Feed water preheaters

- Lethal service

- Steam or process fluid vaporizers

- Boiler or process sample coolers

- Hot water heaters

- High temperature

- Freeze condensers