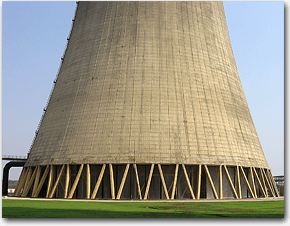

Concrete Cooling Towers:

Concrete cooling towers can be precast or cast in situ. In order to reduce the erection time, in case of stringent time frame and to facilitate the standardization the use of prefabricated elements is preferred. Tailor made Concrete Cooling Towers designed for harsh environment are durable and properly studied to meet projects requirements.

Concrete cooling towers are constructed of RCC outer structure. this Cooling Towers are permanent structures in the industry and find a place where the water requirement is of very high capacities for e.g. in huge fertilizer plants, power plants etc. The internal fill pack material may be of PVC, Wooden Splash, HDPE etc. In addition these Cooling Towers come in various shapes. Our services range from complete designing to testing and commissioning of Concrete cooling towers.

Process:

Concrete cooling towers has a passive Iron Oxide film on the surface. However, Chloride ions from raw/ hard water or seawater make the film permeable, the passivity is destroyed and corrosion can proceed. The rate of corrosion then depends upon the availability of moisture and Oxygen at the surface of the steel, both of which are abundantly available in a cooling tower.

In high quality of this cooling towers the transport of gases and ions is a slow process. However it is much faster through an interconnected network of micro cracks and capillary voids by capillary action. Such a network of micro cracks already exists in reinforced concrete and the widening of cracks in service (by thermal and humidity changes) precede the corrosion process. As soon as the Chloride ions reach the rebar, one has the powerful anodize-catholic potential, and with free moisture abundantly available corrosion will proceed.

Image:

Specification:

- Over-all height and width measured at face adjacent to meld when concrete is cast

- Members ten feet or under: plus or minus 1/8 inch

- Members ten to twenty feet or under: Plus 1/8 inch, minus 3/16 inch

- Members twenty to thirty feet or under: Plus 1/8 inch, minus ¼ inch .

- Member thickness: Plus ¼ inch, minus 1/8 inch

- Out of square (diagonal): 1/8 inch per six feet or ¼ inch total maximum.

Features:

- Concrete cement counter flow cooling towers

- Longest service life in harsh environment

- Erected on site

- Protruded FRP fill support.

- Splash and Film fills in various materials of construction are available.

- The concrete structure is optimized by in house structural engineers to minimize civil costs.

- In house detail engineering ensures quick release of construction drawings and simplified construction methodology.

- Civil construction can be carried out by our own experienced, in house construction group.

- Extensive use of precast elements allows even large cooling towers to be built to meet tight deadlines.

- Optimized designs are available for concrete towers from 400 to 4000 CMH per cell.